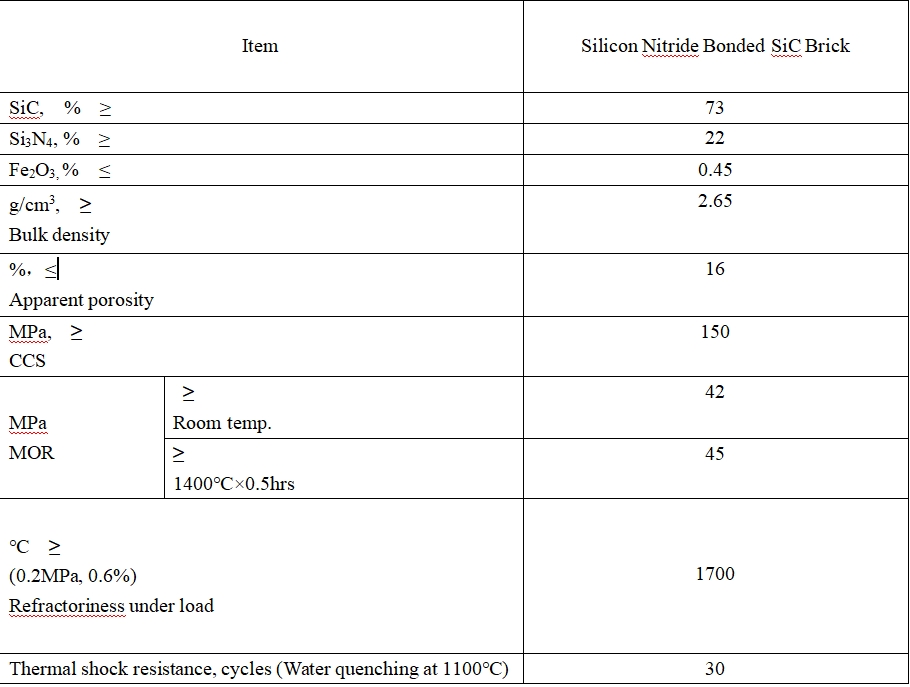

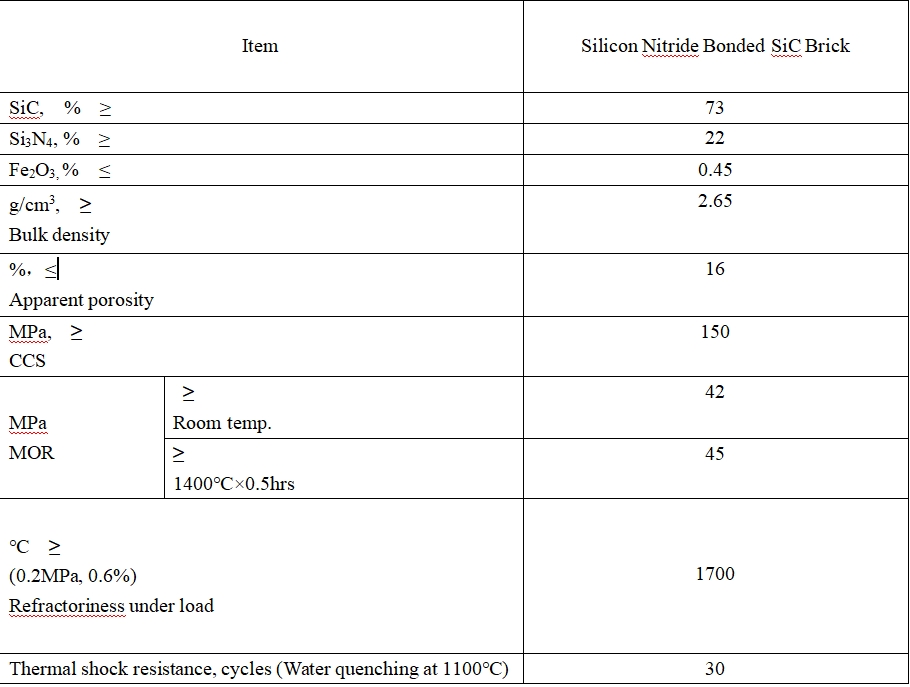

This product is a high cold bending strength silicon nitride bonded silicon carbide brick specially designed for high-temperature kiln heat exchange tubes. It combines advanced material technology with strict quality control to ensure excellent performance in extreme industrial environments. Its room temperature cold bending strength reaches 42MPa, and it still maintains an excellent strength of 45MPa at 1400℃, providing reliable structural support. The apparent porosity is less than 16%, ensuring excellent thermal conductivity and thermal shock stability. At the same time, the load softening temperature is as high as 1700℃, meeting the needs of a variety of harsh high-temperature working conditions. This product is widely used in the aluminum industry, non-ferrous metallurgy, high-temperature kilns and ceramics, and has been certified by large enterprises in many countries. It has excellent and stable quality. It has been strictly tested by independent authoritative laboratories to ensure excellent performance. At the same time, it provides comprehensive technical support and after-sales service to help customers improve production efficiency and extend the service life of equipment. It is the preferred high-end refractory material solution for international trade.

1. High cold bending strength: 42MPa at room temperature and 45MPa at 1400℃, ensuring structural stability;

2. Excellent thermal shock stability: apparent porosity is less than 16%, effectively resisting sudden temperature changes;

3. High load softening temperature: up to 1700℃, suitable for a variety of harsh high temperature environments;

4. Strong corrosion resistance: the materials are tightly bonded to extend the service life;

5. Multi-field recognition: widely used in the aluminum, non-ferrous metallurgy and ceramics industries, and supports certification by large enterprises in many countries;

6. Improve after-sales technical support to ensure customers have worry-free use.

Suitable for high-temperature furnace heat exchange tubes, particularly in high-temperature industries such as the aluminum industry, non-ferrous metal smelting, and high-temperature ceramic manufacturing. Suitable for users who require refractory materials with high temperature resistance, thermal shock resistance, and high mechanical strength, especially large international industrial enterprises and equipment manufacturers.