In the aluminum industry, the lifespan of electrolytic aluminum cells is a critical factor affecting production efficiency and cost. Over the years in this industry, it has been found that the most common pitfall for purchasers is the short lifespan of aluminum cells caused by chemical corrosion. Traditional insulation materials often struggle to withstand the harsh chemical environment inside the aluminum cells, leading to frequent replacements and high maintenance costs. For example, some aluminum plants using traditional insulation materials have to replace their aluminum cells every 3 - 5 years, which significantly impacts production stability and economic benefits.

Vermiculite insulation boards are composed of high - quality vermiculite and other special additives. This unique raw material composition endows them with excellent high - temperature resistance. They can maintain stable physical and chemical properties at temperatures up to 1000°C. The principle behind this high - temperature resistance can be likened to a well - fortified castle. The vermiculite forms a stable framework, and the additives act as the "guards" that prevent the intrusion of high - temperature damage. In a project for a certain aluminum company, the vermiculite insulation boards effectively withstood the high - temperature environment inside the aluminum cell, ensuring normal operation.

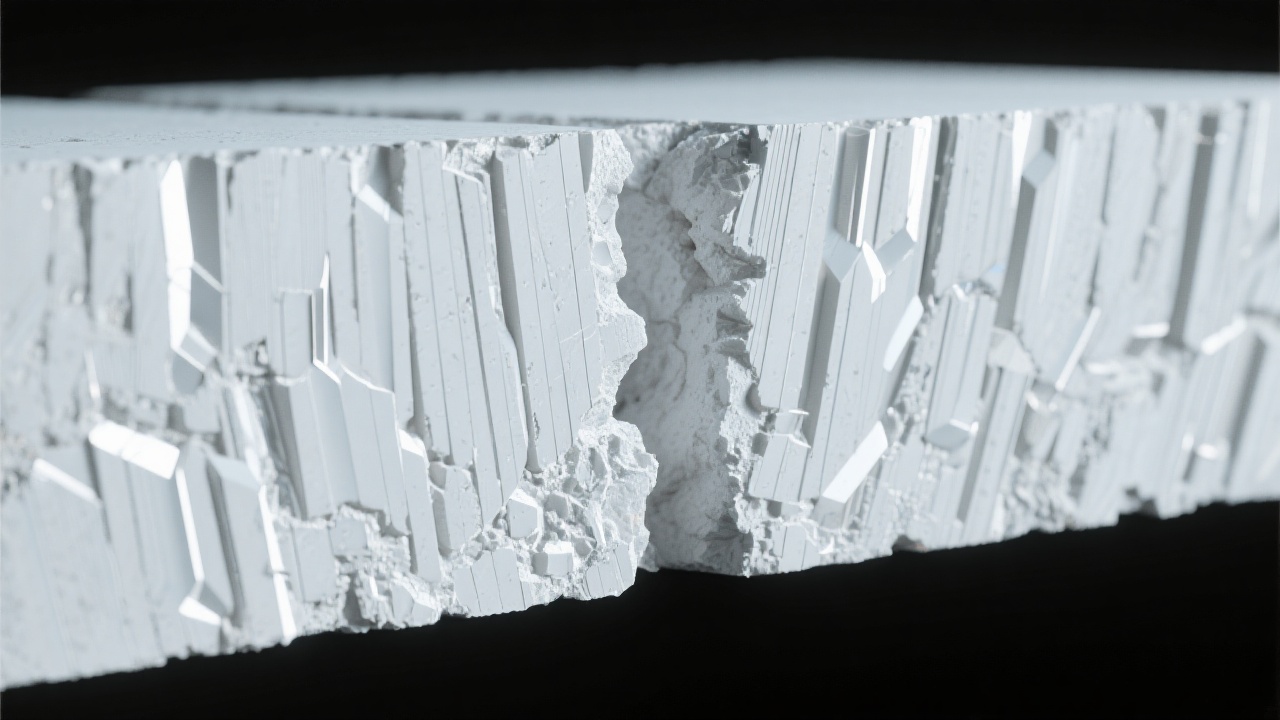

One of the most significant advantages of vermiculite insulation boards is their excellent resistance to fluoride and cryolite corrosion. Through a special formulation and advanced processing technology, they can form a dense protective layer on the surface, effectively preventing the penetration of corrosive substances. Moreover, they can also prevent molten aluminum from wetting the surface, which is crucial for maintaining the integrity of the aluminum cell. In contrast, traditional insulation materials are easily corroded by fluoride and cryolite, and molten aluminum can easily adhere to their surfaces, accelerating the damage of the aluminum cell. According to industry data, the corrosion rate of vermiculite insulation boards is only about 10% of that of traditional insulation materials in the same environment.

When it comes to improving the strength of aluminum cells and reducing the thermal conductivity, vermiculite insulation boards have obvious technical advantages. The high - strength structure of vermiculite insulation boards can effectively support the internal pressure of the aluminum cell, reducing the risk of deformation. At the same time, their low thermal conductivity helps to reduce heat loss, saving energy. The following table shows a comparison between vermiculite insulation boards and traditional insulation materials:

| Material | Strength (MPa) | Thermal Conductivity (W/(m·K)) |

|---|---|---|

| Vermiculite Insulation Board | 15 - 20 | 0.1 - 0.2 |

| Traditional Insulation Material | 8 - 12 | 0.3 - 0.5 |

By using vermiculite insulation boards, the lifespan of aluminum cells can be extended to over 10 years. This significantly reduces the frequency of cell replacements and maintenance costs. In addition, the energy - saving effect brought by the low thermal conductivity also helps to reduce production costs. For instance, a large - scale aluminum plant in Europe replaced its traditional insulation materials with vermiculite insulation boards. After 3 years of operation, the maintenance cost was reduced by 40%, and the energy consumption was decreased by 15%. This clearly demonstrates the practical value of vermiculite insulation boards in terms of extending the lifespan of aluminum cells and reducing production costs.

In conclusion, vermiculite insulation boards offer a comprehensive solution to the problems faced by the aluminum industry in terms of aluminum cell lifespan. Their unique composition, anti - corrosion and anti - wetting abilities, and energy - saving features make them an ideal choice for aluminum plants. If you are looking for a reliable insulation material to improve the performance of your aluminum cells, vermiculite insulation boards are definitely worth considering. Have you encountered similar problems in your industry? You can tell me the specific scenario, and I'll send you 3 solution cases from the same industry. Click here to learn more about our vermiculite insulation boards and take the first step towards optimizing your aluminum production!