In the steel industry, the continuous increase in blast furnace air temperature has become an inevitable trend. As blast furnaces strive for higher production efficiency and better product quality, the demand for air temperature has risen steadily. Traditional refractory materials, such as clay bricks and high - alumina bricks, are facing significant challenges in this context.

Clay bricks, with a relatively low refractory temperature of around 1300 - 1500°C, start to show signs of softening and deformation when the blast furnace air temperature exceeds 1200°C. High - alumina bricks, although having better performance than clay bricks, with a refractory temperature of about 1500 - 1700°C, still cannot fully meet the requirements of high - temperature and high - pressure working conditions in modern blast furnaces. For example, in some large - scale steel plants where the blast furnace air temperature can reach 1350 - 1450°C, the service life of traditional clay bricks and high - alumina bricks is only about 3 - 5 years, and frequent repairs are required, which not only increases maintenance costs but also affects normal production.

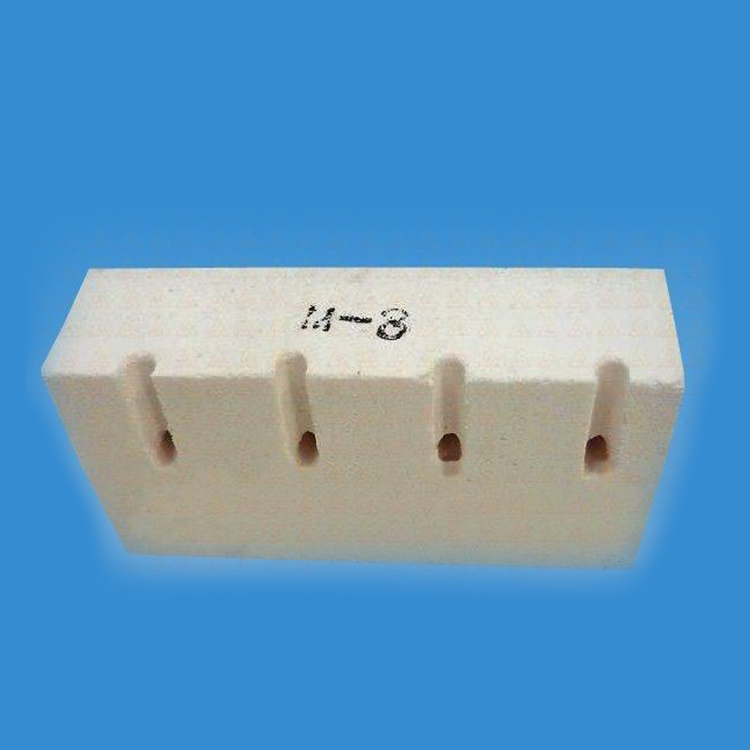

Thermally conductive silica bricks have unique physical and chemical properties that make them well - suited for high - temperature environments in blast furnaces. Firstly, they have a high refractory temperature, generally above 1700°C, which can withstand the ultra - high temperature in the blast furnace.

In terms of creep resistance, thermally conductive silica bricks have a very low creep rate. Under high - temperature and high - pressure conditions, the creep rate of thermally conductive silica bricks is less than 0.5% after 50 hours at 1450°C, while the creep rate of traditional clay bricks can reach more than 2% under the same conditions. This low creep rate ensures the long - term stability of the structure in the blast furnace.

| Refractory Material | Refractory Temperature (°C) | Creep Rate (50h at 1450°C) | Service Life (Years) | Annual Maintenance Cost ($) |

|---|---|---|---|---|

| Clay Bricks | 1300 - 1500 | More than 2% | 3 - 5 | 50,000 - 80,000 |

| High - Alumina Bricks | 1500 - 1700 | About 1.5% | 4 - 6 | 40,000 - 60,000 |

| Thermally Conductive Silica Bricks | Above 1700 | Less than 0.5% | 8 - 10 | 10,000 - 20,000 |

From the table, it is clear that thermally conductive silica bricks have significant advantages in terms of performance and economic benefits. Their long service life and low maintenance cost can bring substantial cost savings to steel enterprises.

Let's take a well - known steel enterprise as an example. After replacing traditional refractory materials with thermally conductive silica bricks in its blast furnace, the service life of the refractory lining has been extended from 4 years to 8 years. The annual maintenance cost has been reduced from $50,000 to $15,000. Moreover, due to the more stable operation of the blast furnace, the production efficiency has increased by about 10%, and the product quality has also been improved.

Another medium - sized steel plant found that after using thermally conductive silica bricks, the energy consumption of the blast furnace decreased by about 8% because of the better thermal conductivity of the silica bricks, which means significant cost savings in the long run.

Thermally conductive silica bricks are becoming the new standard in the steel industry. They not only bring economic benefits to steel enterprises but also enhance their competitiveness in the market. By reducing maintenance costs, improving production efficiency, and ensuring product quality, thermally conductive silica bricks help steel enterprises achieve long - term business growth and cost optimization.

If you are a steel enterprise looking for high - performance refractory materials, thermally conductive silica bricks are your ideal choice. Don't miss this opportunity to revolutionize your blast furnace operations and gain a competitive edge in the market. Click here to learn more about thermally conductive silica bricks and how they can benefit your business!