The aluminum industry today faces immense pressure to optimize operational costs while embracing sustainable production. High energy consumption coupled with frequent equipment maintenance particularly impacts electrolytic aluminum cells — critical components known for their intensive heat demands and corrosive environments. This article explores the pioneering use of vermiculite insulation boards as a breakthrough solution that not only reduces thermal losses but also prolongs electrolytic cell service life, thereby significantly cutting maintenance expenses.

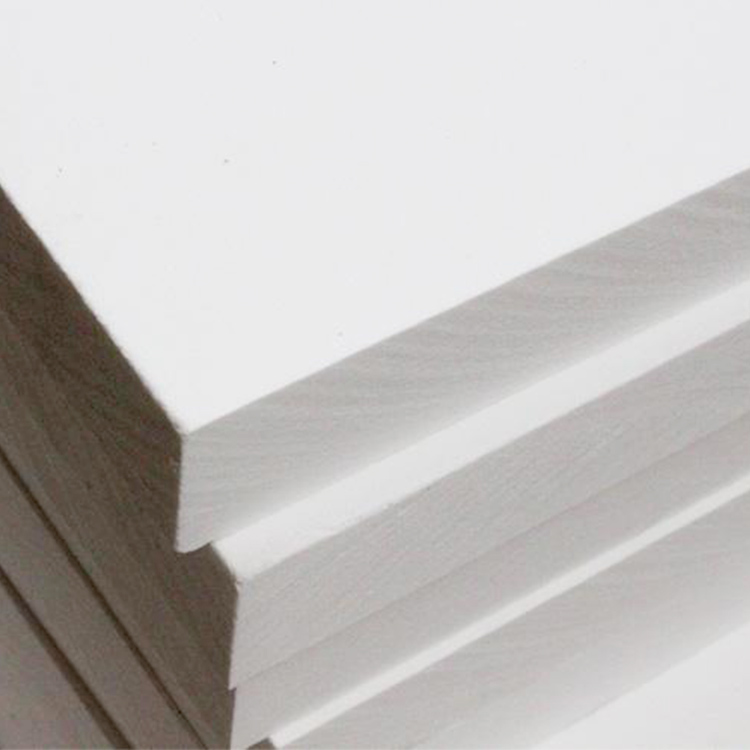

Vermiculite, a hydrated magnesium aluminum silicate mineral, features an inherent multilayered crystalline structure offering low thermal conductivity and excellent heat resistance. Leveraging advanced processing techniques, manufacturers optimize vermiculite boards to achieve superior density uniformity, minimal porosity, and enhanced resistance to chemical corrosion. These characteristics make vermiculite insulation boards ideal for high-temperature applications like electrolytic aluminum cells, where traditional insulation materials often degrade prematurely.

Extensive laboratory and field studies have demonstrated that vermiculite insulation boards maintain structural integrity even beyond 1100°C, sharply reducing heat dissipation compared to conventional firebrick linings by up to 30%. The low thermal conductivity (approx. 0.07 W/m·K at operating temperatures) minimizes heat loss, stabilizing cell temperatures and limiting thermal stress cycles that accelerate refractory wear.

Moreover, the boards’ chemical inertness counters corrosive fluoride attacks common in aluminum electrolysis environments, safeguarding the cell lining. This dual protection—thermal and chemical—translates into a prolonged refractory lifespan, reducing unplanned shutdowns and maintenance frequency by nearly 25%, according to industry pilot projects.

A top aluminum producer in China implemented vermiculite insulation boards across multiple electrolytic cells with remarkable results. Over an 18-month monitoring period, energy consumption per metric ton of aluminum drop by 8.5%, primarily attributed to reduced heat loss. Simultaneously, the maintenance interval extended from every 12 months to over 16 months, markedly lowering labor and refractory replacement costs.

Industry experts, including Dr. Li Fang from the Aluminum Industrial Technology Institute, highlight: "Using vermiculite insulation boards aligns perfectly with the sector’s green transition goals. Their durability and insulation performance exceed current standards, enabling sustainable production without compromising efficiency."

.jpg)

As global regulators tighten emissions standards and energy costs continue rising, aluminum manufacturers must adopt solutions with proven environmental and economic benefits. Vermiculite insulation boards contribute decisively by lowering operational carbon footprints through decreased fuel consumption and reducing the frequency and scale of refractory repairs that generate industrial waste.

Adoption of these boards dovetails with corporate sustainability commitments and enhances production continuity—key competitive advantages in today’s demanding markets. Forward-looking companies integrating vermiculite boards position themselves as industry leaders in innovation and responsible manufacturing.