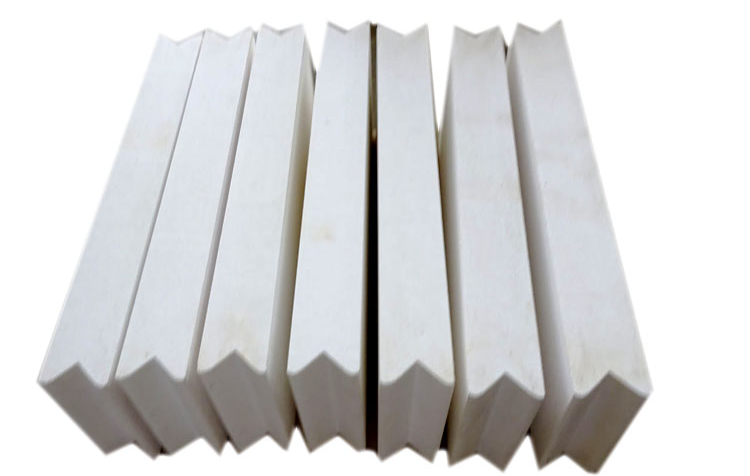

The refractory material industry plays a crucial role in various high - temperature industrial sectors such as steelmaking, non - ferrous metal smelting, and glass manufacturing. These materials are essential for lining furnaces, kilns, and other high - temperature equipment, ensuring their efficient and safe operation. Among the numerous refractory materials, silicon nitride bonded silicon carbide bricks have emerged as a high - performance option.

Silicon nitride bonded silicon carbide bricks possess several outstanding performance advantages. Firstly, they have high strength. Tests have shown that their compressive strength can reach up to 300 MPa, which enables them to withstand high pressures in high - temperature environments. Secondly, their thermal conductivity is excellent, with a thermal conductivity coefficient of about 20 - 30 W/(m·K). This property allows for efficient heat transfer, reducing energy consumption in industrial processes.

In addition, these bricks have good corrosion resistance. In acid - base corrosion tests, they showed a weight loss of less than 5% after being immersed in strong acid or alkali solutions for 100 hours, indicating their long - term durability in corrosive environments. Their oxidation resistance is also remarkable. After being exposed to high - temperature oxidation environments for 200 hours, the oxidation layer thickness was less than 0.5 mm.

The path to international recognition for silicon nitride bonded silicon carbide bricks has been a long - standing effort. Initially, the product faced challenges in entering the international market due to fierce competition and strict quality requirements. However, through continuous R & D and quality improvement, the product gradually met international standards.

The company participated in many international industry exhibitions and technical exchanges, which allowed the product to gain more exposure. After several years of hard work, it finally caught the attention of international large - scale companies.

A well - known European steel company was facing problems with the short service life of refractory materials in its blast furnaces. After using silicon nitride bonded silicon carbide bricks, the service life of the furnace lining was extended from 1 year to 2.5 years, significantly reducing maintenance costs and improving production efficiency. Another American glass manufacturing company replaced its original refractory materials with these bricks. As a result, the energy consumption of the glass melting furnace was reduced by 15%, and the quality of the glass products was also improved.

Currently, silicon nitride bonded silicon carbide bricks have a significant market share in the international market. More than 80% of the company's production is supplied to more than ten countries and regions, especially in Europe and America. In the European market, the product has occupied about 30% of the high - end refractory material market, and in the American market, this figure is about 25%.

Silicon nitride bonded silicon carbide bricks have proven their value through excellent performance, international recognition, and successful customer cases. If you are a global purchaser looking for high - quality refractory materials, this product is definitely worth considering.

Interested in learning more about our silicon nitride bonded silicon carbide bricks? Contact us at [Contact Email] or call [Contact Phone Number] to get detailed product information and personalized solutions.