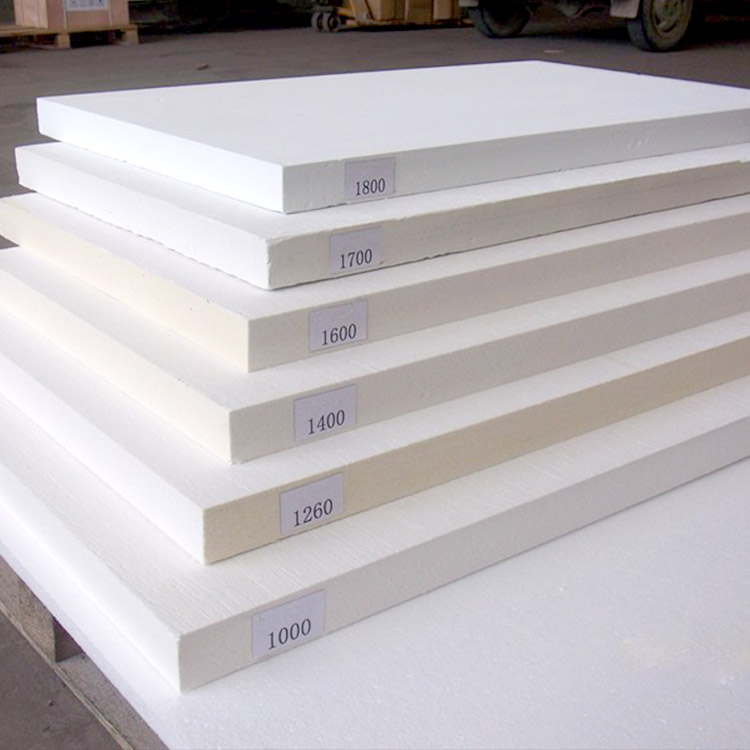

High-temperature corrosion presents a persistent challenge for ceramic manufacturing, affecting kiln longevity and increasing maintenance costs. Traditional refractory materials often fall short under extreme thermal stress and corrosive environments, leading to frequent downtime and reduced production efficiency. Silicon nitride bonded silicon carbide (Si3N4-SiC) bricks have emerged as a superior solution, combining high mechanical strength, excellent thermal conductivity, and remarkable resistance to thermal shock and chemical attack.

Silicon nitride bonded silicon carbide bricks are engineered to endure the harshest kiln conditions, thanks to their unique microstructure:

An independent laboratory testing report confirms that silicon nitride bonded silicon carbide bricks reduce corrosion depths by up to 75% compared to traditional fireclay bricks after 1000 hours of exposure at 1450°C in aggressive kiln environments.

Multiple internationally recognized ceramics producers across Europe and North America have incorporated Si3N4-SiC bricks into their kiln linings with outstanding results:

These clients reported significant reductions in unplanned downtime and noted that using Si3N4-SiC bricks also contributed to overall kiln energy efficiency improvements, thanks to better insulation properties and heat retention.

Unlike conventional fireclay or alumina bricks, the silicon nitride bonded silicon carbide bricks offer a compelling total cost of ownership advantage:

| Feature | Conventional Fireclay/Alumina Brick | Silicon Nitride Bonded Silicon Carbide Brick |

|---|---|---|

| Campaign Life | 12–18 months | 24–30 months |

| Thermal Shock Resistance | Low (10–15 cycles) | High (30+ cycles) |

| Corrosion Resistance | Moderate | Excellent |

| Total Cost Savings | - | Up to 25% over lifecycle |

Despite a higher upfront investment, the reduced frequency of kiln relining, fewer maintenance shutdowns, and improved operational efficiencies result in measurable long-term savings and return on investment.

Silicon nitride bonded silicon carbide bricks have gained worldwide recognition, currently serving over a dozen major ceramic manufacturers in Europe, North America, and Asia. With approximately 80% of production destined for export markets, this refractory technology enjoys a robust competitive edge due to:

Industry feedback emphasizes that switching to Si3N4-SiC bricks not only improves kiln uptime but also contributes to sustainable production practices through enhanced energy efficiency.

When high-temperature corrosion and kiln relining frequency curb productivity in ceramic manufacturing, silicon nitride bonded silicon carbide bricks offer a proven alternative. Especially suited for demanding applications involving rapid heating cycles, aggressive atmospheres, and the need for energy-saving solutions, this refractory material delivers exceptional lifecycle performance.

Request detailed technical datasheets or schedule a factory tour today.