Refractory materials play a crucial role in high-temperature industrial applications such as metallurgy, ceramics, and mining. Among the many refractory products available, nitride-bonded silicon carbide bricks have emerged as a top choice for their exceptional performance and global recognition.

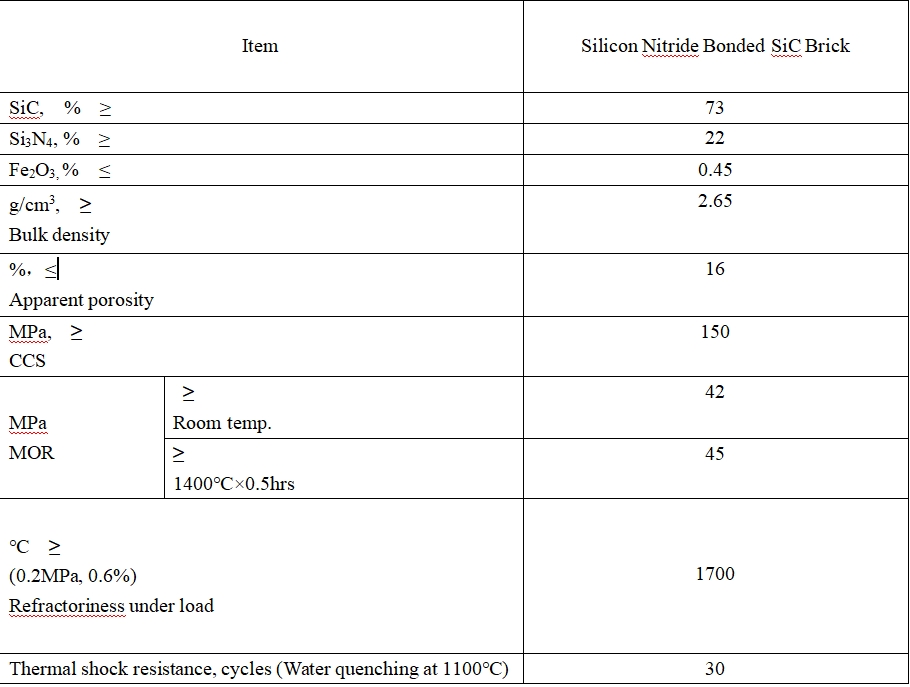

Nitride-bonded silicon carbide bricks are engineered to withstand extreme thermal and mechanical stresses. With a high flexural strength of up to 45 MPa and a thermal conductivity of 18 W/m·K, these bricks offer superior heat transfer efficiency and structural integrity under harsh conditions.

Independent laboratory tests conducted by leading international testing institutions have confirmed the product’s excellent resistance to thermal shock and chemical erosion. These results validate its suitability for use in demanding environments such as smelting furnaces, kilns, and high-temperature processing systems.

Over the past decade, nitride-bonded silicon carbide bricks have gained widespread acceptance among major industrial players across the globe. More than 80% of the production volume is exported to over 20 countries and regions, with a significant portion reaching Europe and North America.

Several multinational corporations in the metallurgical and ceramic industries have integrated this product into their production lines. One such example is a leading European steelmaker, which reported a 25% increase in furnace life after switching to nitride-bonded silicon carbide bricks.

These bricks have been successfully adopted by some of the world's largest manufacturers in the metal and mineral processing sectors. In Asia, a major Chinese non-ferrous metal company has used the product in its high-temperature smelting processes, achieving improved energy efficiency and reduced maintenance costs.

Another case study involves a U.S.-based ceramic manufacturer that replaced traditional refractory materials with nitride-bonded silicon carbide bricks. The result was a 30% reduction in thermal loss and a significant improvement in product consistency.

The market presence of nitride-bonded silicon carbide bricks is supported by solid data. According to internal sales records, the product has been supplied to more than 10 large-scale industrial clients internationally, with a growing demand from emerging markets in Southeast Asia and Latin America.

| Region | Market Share | Key Clients |

|---|---|---|

| Europe | 35% | Steel and Ceramic Manufacturers |

| North America | 25% | Metallurgical Plants |

| Asia | 30% | Non-Ferrous Metal Producers |

With a proven track record of reliability, performance, and international trust, our nitride-bonded silicon carbide bricks are an ideal solution for your high-temperature industrial needs. Whether you're looking to improve furnace efficiency, reduce downtime, or enhance product quality, our product delivers consistent value.

As we continue to expand our global footprint, we invite you to explore how our refractory solutions can benefit your operations. Don’t miss the opportunity to partner with a trusted supplier that meets the highest standards of quality and innovation.