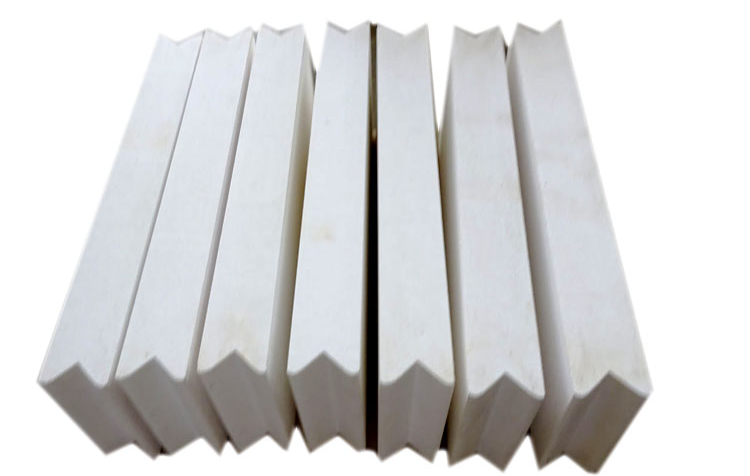

Refractory materials play a crucial role in industries such as non - ferrous mining, metallurgical blast furnaces, and the ceramic industry. They are essential for withstanding high temperatures, chemical corrosion, and mechanical stress, ensuring the smooth operation of industrial processes. Among these refractory materials, silicon nitride bonded silicon carbide bricks have emerged as a top - choice product for many international companies.

Silicon nitride bonded silicon carbide bricks possess several remarkable performance advantages. Firstly, they have high strength. In a laboratory test, the compressive strength of these bricks can reach up to 300 MPa, which allows them to maintain their structural integrity under heavy loads in high - temperature environments. Secondly, their excellent thermal conductivity, with a thermal conductivity coefficient of about 20 W/(m·K), enables efficient heat transfer, reducing energy consumption in industrial furnaces.

In addition, these bricks have good corrosion resistance. They can resist the erosion of various molten metals and slags, which is of great significance for the long - term operation of equipment in non - ferrous metallurgy. After a series of strict tests in different industrial environments, the performance of silicon nitride bonded silicon carbide bricks has been fully verified, and they have shown excellent stability and durability.

Over the years, silicon nitride bonded silicon carbide bricks have gradually gained the recognition of international large - scale companies. Through continuous research and development and improvement of production technology, the quality of these bricks has been continuously enhanced. At the beginning, the product was mainly used in domestic markets, but with its excellent performance, it began to attract the attention of international buyers.

Many well - known foreign companies have established long - term cooperation with the manufacturers of silicon nitride bonded silicon carbide bricks. For example, a large non - ferrous metallurgy company in the United States has been using these bricks in its blast furnaces for five years. They reported that after using these bricks, the service life of the furnace lining has been extended by 30%, and the energy consumption has been reduced by 15%. Another ceramic company in Germany also highly praised the thermal conductivity and corrosion resistance of these bricks, which have significantly improved the quality of their ceramic products.

Silicon nitride bonded silicon carbide bricks have a strong presence in the international market. More than 80% of the production volume is supplied to more than ten countries and regions, especially in Europe and America. In the European market, they account for 20% of the total refractory material market share in the non - ferrous metallurgy industry. In the American market, this figure reaches 15%. In addition, many large domestic non - ferrous metallurgy companies have also purchased these bricks, which further demonstrates their excellent quality and market competitiveness.

If you are a global purchaser in the consideration stage, we invite you to further understand our silicon nitride bonded silicon carbide bricks. Our products have been proven by international large - scale companies, and we are confident that they will meet your industrial needs. Please feel free to contact us at [contact email] or call us at [contact phone number]. Let's work together to create a better future for your industry!