High-temperature industrial sectors such as non-ferrous metallurgy, blast furnace operations, and ceramic manufacturing continually demand refractory materials that can withstand extreme conditions without degradation. Silicon Nitride Bonded Silicon Carbide Bricks (SN-SiC bricks) have emerged as a benchmark, addressing critical pain points with their superior mechanical and thermal properties. Supported by rigorous third-party laboratory tests and trusted by over a dozen international leaders and prominent domestic metallurgical firms, these bricks stand out as a reliable solution to extend equipment lifespan and optimize production efficiency.

Operators in non-ferrous mining face severe chemical corrosion due to aggressive slag compositions and fluctuating process temperatures. Similarly, blast furnaces require materials that can endure rapid thermal cycling and mechanical stress to maintain furnace integrity and energy efficiency. The ceramic industry seeks longer-lasting kiln linings capable of resisting thermal shock and chemical wear during firing cycles.

Traditional refractories often fall short in one or more of these areas, resulting in frequent maintenance shutdowns and increased operational costs.

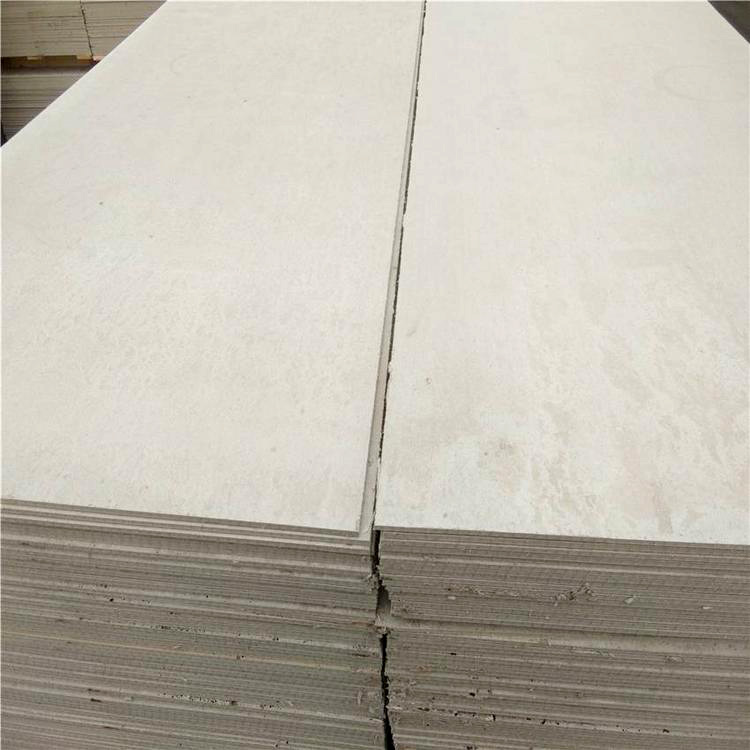

SN-SiC bricks combine silicon nitride’s superior bonding capability with the intrinsic hardness and chemical stability of silicon carbide, delivering an exceptionally durable refractory. Key characteristics include:

Independent laboratory analyses corroborate these attributes, reinforcing the bricks’ reliability for harsh operational environments.

These distinctive qualities enable SN-SiC bricks to excel in diverse high-temperature applications:

In copper and nickel smelting, the bricks sustain strong chemical erosion from flux and molten slag. One leading European non-ferrous producer reported a 25% extension in lining life and a 15% reduction in downtime by retrofitting key zones with SN-SiC bricks.

Blast furnace operators in Asia have adopted SN-SiC bricks within the bosh and tuyere areas, leveraging their thermal shock resistance to minimize brittle cracking. This upgrade resulted in a direct improvement of thermal efficiency by over 10%, translating into fuel savings and increased output stability.

Ceramics manufacturers value the bricks’ ability to extend kiln receptor life by resisting chemical wear and rapid firing cycles. A top Chinese ceramic plant recorded kiln lining service life improvement exceeding 30%, dramatically reducing maintenance frequency and cost.

SN-SiC bricks are widely accepted by key global players — over 80% of produced bricks are exported to Europe and North America, serving leading multinational corporations in their most demanding processes. Domestically, top-tier metallurgical companies have integrated these bricks into their standard refractory specifications after rigorous in-plant testing, endorsing their superior performance.

“Our partnership with SN-SiC refractory suppliers has enabled us to drastically reduce unscheduled downtime and improve furnace throughput,” noted a senior engineer from a European metallurgical conglomerate.

For industries demanding:

SN-SiC bricks offer an optimal, proven solution. Their adoption contributes to lowering the Total Cost of Ownership (TCO) while enabling your equipment to remain operational longer and more reliably.