In the fields of non - ferrous mines, metallurgical blast furnaces, and the ceramic industry, the demand for high - performance refractory materials has reached an urgent level. With the continuous development of these industries, traditional refractory materials can no longer meet the requirements of high - temperature, high - pressure, and complex chemical environments. Therefore, the market is in dire need of a new type of refractory material that can provide long - term stability and high efficiency.

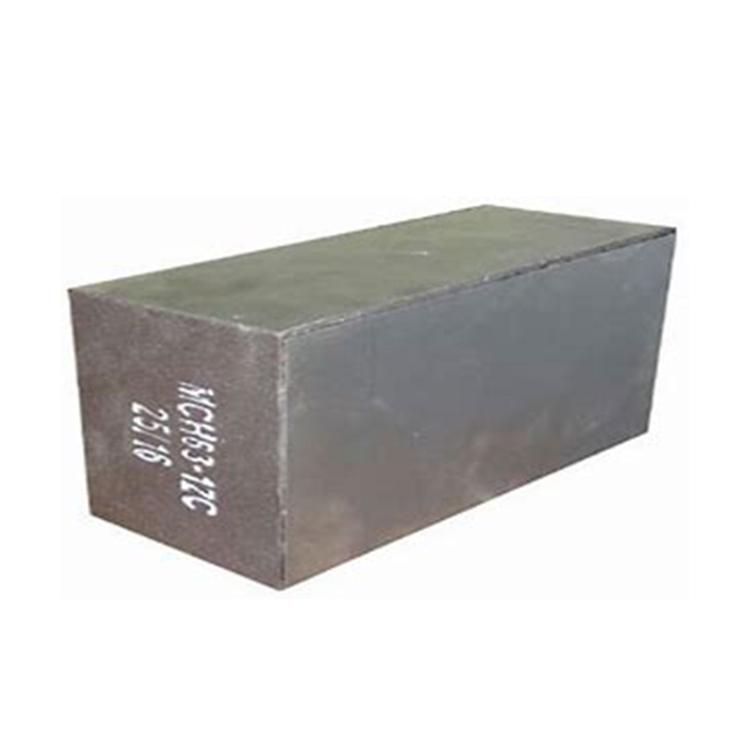

Silicon nitride - bonded silicon carbide bricks stand out among various refractory materials. They have high strength, which allows them to withstand significant mechanical stress in high - temperature environments. For example, in some high - temperature industrial furnaces, these bricks can maintain their shape and structure without being easily damaged. Their excellent thermal conductivity is another key advantage. It can quickly transfer heat, reducing the temperature difference inside the furnace and improving energy utilization efficiency. In addition, their outstanding thermal shock resistance enables them to resist sudden temperature changes without cracking or spalling.

Compared with traditional refractory materials, silicon nitride - bonded silicon carbide bricks have a longer service life. Traditional bricks may need to be replaced every 6 - 8 months, while silicon nitride - bonded silicon carbide bricks can last for 12 - 18 months, reducing the frequency of replacement and maintenance costs.

Laboratory test results show that silicon nitride - bonded silicon carbide bricks have a compressive strength of up to 150 MPa, which is 30% higher than that of ordinary refractory bricks. Their thermal conductivity can reach 20 - 30 W/(m·K), which is much higher than that of traditional materials.

In non - ferrous mines, silicon nitride - bonded silicon carbide bricks are used in the lining of smelting furnaces. Their high strength and corrosion resistance can effectively resist the erosion of molten metals and slag. For example, in a copper smelting plant, the use of these bricks has reduced the corrosion rate of the furnace lining by 40%, greatly improving the service life of the furnace.

In metallurgical blast furnaces, these bricks play a crucial role in the hearth and bosh areas. Their excellent thermal conductivity helps to maintain a stable temperature distribution in the furnace, improving the quality of ironmaking. According to statistics, in some large - scale blast furnaces, the use of silicon nitride - bonded silicon carbide bricks has increased the iron output by 10 - 15%.

In the ceramic industry, silicon nitride - bonded silicon carbide bricks are used in kilns. Their high - temperature stability and low thermal expansion coefficient ensure the quality of ceramic products. For example, in a high - end ceramic production line, the use of these bricks has reduced the defective rate of products by 20%.

Silicon nitride - bonded silicon carbide bricks have gained high international recognition, especially in the European and American markets. About 80% of the products are exported to these regions. In addition, they have also established long - term partnerships with many domestic leading enterprises. For example, they have provided refractory solutions for several well - known non - ferrous metal smelting enterprises and ceramic manufacturers, helping these enterprises to improve production efficiency and product quality.

With a large number of successful cases and authoritative test data, silicon nitride - bonded silicon carbide bricks have proven their high credibility and strong industry adaptability. Whether you are in the non - ferrous mining, metallurgical, or ceramic industry, this product can provide you with a reliable refractory solution, making your production line more stable and efficient.

Discover How Silicon Nitride - Bonded Silicon Carbide Bricks Can Transform Your Business!