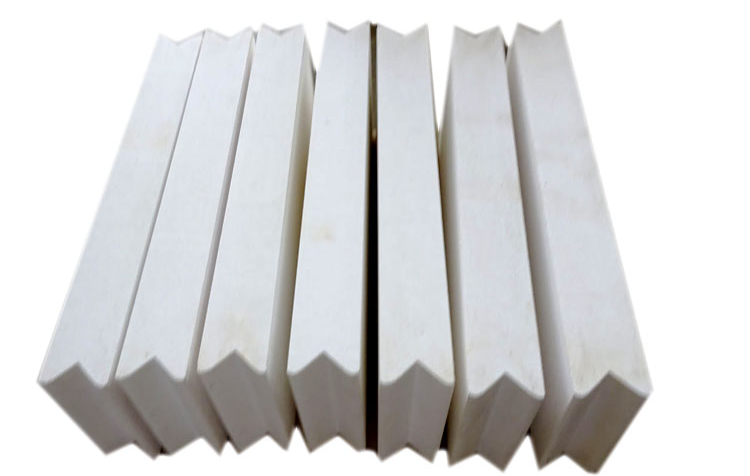

In today's advanced high-temperature industrial environments, the demand for refractory materials that deliver exceptional durability, thermal stability, and chemical resistance is paramount. Silicon nitride combined with silicon carbide bricks (Si3N4-SiC bricks) have emerged as a leading solution, redefining industry standards across sectors like non-ferrous mining, metallurgical blast furnaces, and the ceramic industry.

Industries such as non-ferrous metal extraction, high-temperature metallurgy, and advanced ceramics face rigorous operating conditions involving extreme temperatures, thermal cycling, and aggressive chemical exposure. Failure of refractory linings here results in costly downtime and reduced operational efficiency. Silicon nitride combined with silicon carbide bricks provide a robust answer by merging the best properties of their constituents — high mechanical strength, superior thermal conductivity, excellent corrosion resistance, and remarkable resistance to thermal shock.

Multiple rigorous evaluations performed by independent laboratories confirm the superior capabilities of these composite bricks:

| Performance Metric | Measured Value | Industrial Benchmark |

|---|---|---|

| Cold Crushing Strength | > 120 MPa | 80-100 MPa |

| Thermal Conductivity (at 1000°C) | 35 W/m·K | 20-30 W/m·K |

| Thermal Shock Resistance | Up to 25 cycles sustained | 15-20 cycles |

| Chemical Corrosion Resistance | Minimal weight loss & surface degradation | Moderate degradation in comparable bricks |

These superior properties translate directly to prolonged service life and reduced maintenance for end customers, which is why the bricks have outperformed conventional refractory materials in demanding applications globally.

With over 80% of production exported, silicon nitride combined with silicon carbide bricks enjoy widespread adoption across Europe, North America, and multiple Asia-Pacific countries. More than a dozen multinational corporations in the non-ferrous metal mining and metallurgy sectors have integrated these bricks into their operations, citing enhanced uptime, lower operational costs, and improved furnace performance.

One European copper refinery reported a 15% increase in furnace campaign life after switching to these composite bricks, reducing unplanned shutdowns and achieving significant energy savings. An American ceramics manufacturer highlighted the bricks’ exceptional thermal shock resistance as key to maintaining high product quality and process stability during rapid temperature cycles.

Originating from a dedicated R&D initiative to overcome the limitations of traditional refractory bricks, this silicon nitride and silicon carbide combination evolved through innovative material engineering and process optimization. Early prototypes underwent extensive trials at both pilot plants and industrial sites, validating theoretical benefits through practical results.

The turning point came with independent certifications confirming compliance with international refractory standards. This milestone unlocked new markets and fostered long-term partnerships with leading companies, each incentivized by the material’s clear operational advantages. Continuous improvements and customization have since cemented the product’s position at the forefront of refractory technology.

For global procurement professionals focused on maximizing furnace longevity, minimizing downtime, and optimizing operational costs, silicon nitride combined with silicon carbide bricks represent a smart strategic investment supported by comprehensive data and trusted validations.

Contact us to receive detailed technical datasheets, case studies, and tailor-made proposals that fit your industry's unique demands.

Request More Information Now