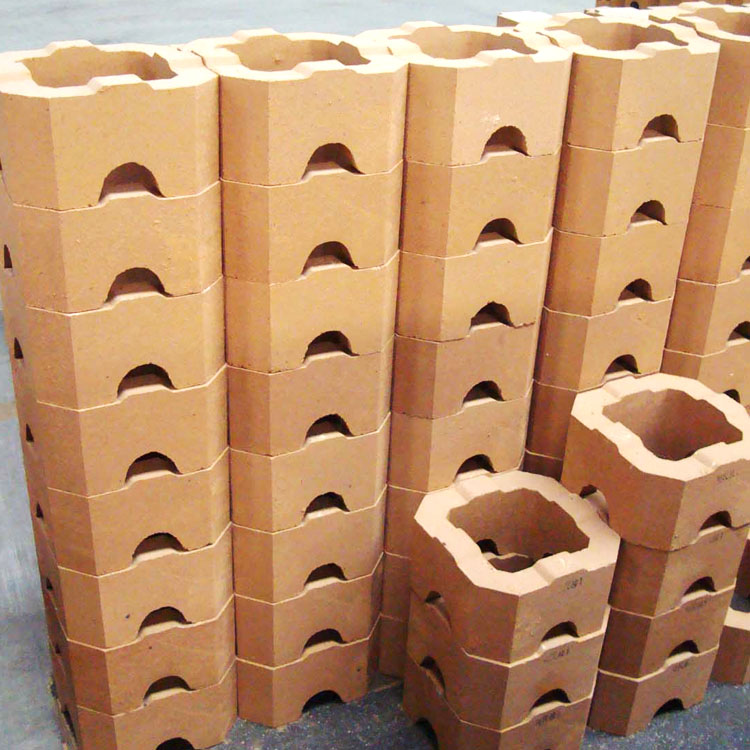

In high-temperature industrial settings such as metallurgy and glass production, magnesia-chrome bricks play a crucial role. These bricks are essential for lining furnaces and other high-temperature equipment, providing insulation and protection against extreme heat and chemical corrosion.

There are two main types of magnesia-chrome bricks: unfired magnesia-chrome bricks and directly bonded magnesia-chrome bricks. Unfired magnesia-chrome bricks are made by mixing magnesia and chrome ore with a binder and then pressing them into shape. They are relatively easy to manufacture and have good initial strength. However, they have some limitations. For example, their high-temperature performance may not be as good as that of directly bonded magnesia-chrome bricks, and they may have a shorter service life.

Directly bonded magnesia-chrome bricks are produced through a high-temperature firing process, which results in a strong bond between the magnesia and chrome components. This gives them several significant advantages over unfired magnesia-chrome bricks.

Firstly, they have excellent high-temperature strength. They can withstand temperatures up to 1800°C without significant deformation, which is 200°C higher than the maximum temperature that unfired magnesia-chrome bricks can typically endure. This high-temperature strength ensures that the bricks maintain their structural integrity in the most extreme industrial environments.

Secondly, directly bonded magnesia-chrome bricks have better chemical resistance. They are more resistant to the corrosive effects of molten metals, slags, and gases, which helps to extend their service life. In some cases, the service life of directly bonded magnesia-chrome bricks can be up to 50% longer than that of unfired magnesia-chrome bricks.

Directly bonded magnesia-chrome bricks are widely used in high-temperature production processes in various industries, including metallurgy, glass, and cement production.

In the metallurgical industry, they are used in steelmaking furnaces, electric arc furnaces, and ladles. Their high-temperature strength and chemical resistance help to improve the efficiency of the steelmaking process and reduce production costs. For example, in a steelmaking plant, the use of directly bonded magnesia-chrome bricks can reduce the frequency of furnace repairs by up to 30%, resulting in significant savings in maintenance costs.

In the glass industry, directly bonded magnesia-chrome bricks are used in glass melting furnaces. They can withstand the high temperatures and corrosive environment in the furnace, ensuring a stable glass production process. This can lead to an increase in glass quality and a reduction in production defects.

Let's take a look at a real-world example of a company that has benefited from using directly bonded magnesia-chrome bricks. A medium-sized metallurgical enterprise was facing challenges with high production costs and inconsistent product quality due to the frequent replacement of furnace lining materials.

After switching to directly bonded magnesia-chrome bricks, the company noticed significant improvements. The service life of the furnace lining increased from an average of 6 months to 9 months, a 50% increase. This led to a reduction in maintenance costs by approximately 25%. Moreover, the production quality improved significantly, with a decrease in product defects by 15%.

These improvements not only enhanced the company's competitiveness in the market but also increased its profitability. The company was able to produce higher-quality products at a lower cost, which allowed it to gain a larger market share.

In conclusion, directly bonded magnesia-chrome bricks offer numerous advantages over unfired magnesia-chrome bricks. Their excellent high-temperature strength, chemical resistance, and long service life make them an ideal choice for high-temperature industrial applications. They can significantly improve production quality, reduce maintenance costs, and enhance a company's competitiveness in the global market.

If you are looking for a reliable refractory material to improve your production process and reduce costs, directly bonded magnesia-chrome bricks are the answer. Contact us today to learn more about our products and how they can benefit your business!