In the highly competitive refractory materials industry, silicon nitride bonded silicon carbide bricks have emerged as a remarkable solution, capturing the attention of global players. These bricks are not just another product; they are a game - changer in industries such as non - ferrous mines, metallurgical blast furnaces, and the ceramic industry.

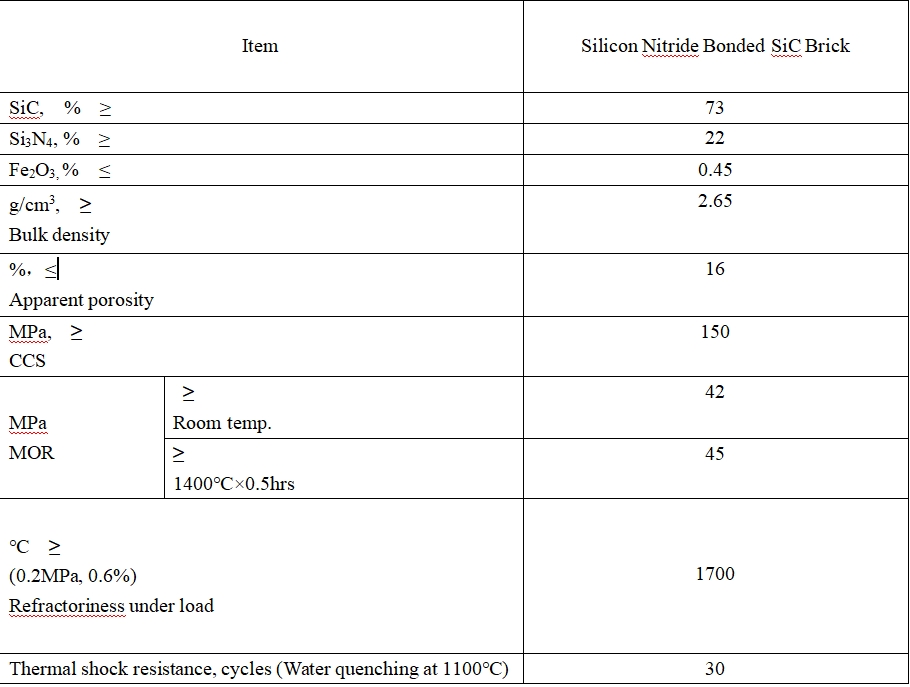

Silicon nitride bonded silicon carbide bricks possess a unique set of performance advantages. Firstly, they have high strength. Laboratory tests show that under high - pressure conditions, these bricks can withstand up to 300 MPa of pressure, far exceeding many other refractory materials on the market. This high - strength characteristic makes them ideal for use in harsh industrial environments, such as the inner linings of metallurgical blast furnaces, where they can resist the impact and pressure generated during the smelting process.

Secondly, their excellent thermal conductivity is a significant advantage. With a thermal conductivity of up to 20 W/(m·K), they can quickly transfer heat, improving the efficiency of heat utilization in industrial processes. For example, in the ceramic industry, this property helps to reduce the firing time of ceramics, thereby increasing production efficiency and reducing energy consumption.

In addition, these bricks have good corrosion resistance. In acidic and alkaline environments, their mass loss rate after long - term immersion is less than 5%, ensuring their long - term stability and reliability in various chemical environments.

Initially, silicon nitride bonded silicon carbide bricks were relatively unknown in the international market. However, through continuous research and development, quality improvement, and active participation in international exhibitions, they gradually caught the attention of international large - scale companies. After a series of strict quality inspections and practical tests, these bricks have been recognized by international authorities for their outstanding performance.

Over a dozen large overseas companies have adopted silicon nitride bonded silicon carbide bricks in their production processes. One well - known European metallurgical company reported that after replacing their original refractory materials with these bricks, the service life of their blast furnace lining increased by 30%, and the energy consumption per unit of steel production decreased by 15%. Another North American ceramic manufacturer mentioned that the use of these bricks in their kilns improved the firing quality of their products and increased the production capacity by 20%.

"The silicon nitride bonded silicon carbide bricks have brought us unexpected benefits. Their high - quality performance has significantly improved our production efficiency and product quality," said a production manager from a European company.

.jpg)

Currently, more than 80% of the production of silicon nitride bonded silicon carbide bricks is supplied to more than ten countries and regions, especially in Europe and the United States. This shows the high level of international recognition and trust in these products.

If you are in the consideration stage of choosing refractory materials, don't miss out on the opportunity to learn more about silicon nitride bonded silicon carbide bricks. Our professional team is ready to provide you with detailed product information and technical support. Contact us at [Contact Email] or visit our website [Website URL] to start your journey towards more efficient and reliable industrial production!