In the realm of high-temperature industries, such as metallurgy and glass manufacturing, selecting the right refractory material is crucial. These industries face numerous challenges when it comes to materials, including high temperatures, corrosion, and mechanical stress. The wrong choice of refractory material can lead to increased production costs, reduced efficiency, and even production disruptions. In this context, ordinary magnesia-chrome bricks emerge as a reliable solution.

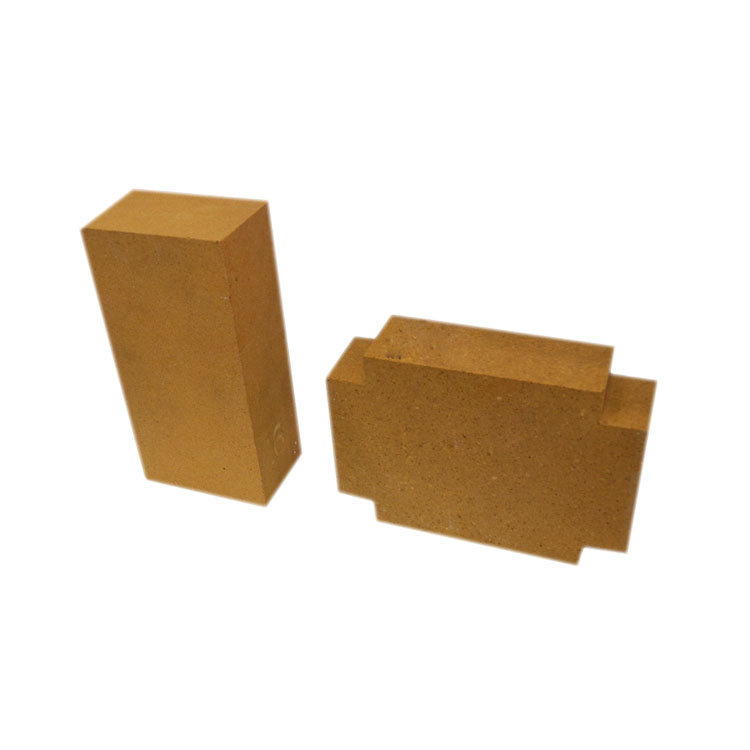

Ordinary magnesia-chrome bricks are made from high-quality magnesia and chrome ore, which endow them with several remarkable properties. First of all, they have high strength. Tests show that the compressive strength of ordinary magnesia-chrome bricks can reach up to 50 MPa, which allows them to withstand significant mechanical stress in high-temperature environments without cracking or deforming easily.

Secondly, their corrosion resistance is outstanding. In harsh chemical environments with strong acids or alkalis, ordinary magnesia-chrome bricks can resist corrosion effectively. For example, in some metallurgical processes where there are high concentrations of slag and metal oxides, the corrosion rate of these bricks is less than 5% per year, ensuring a long service life.

Thirdly, they have excellent erosion resistance. In high-velocity gas or liquid flow environments, such as in some glass melting furnaces, ordinary magnesia-chrome bricks can resist the scouring of high-temperature molten materials, maintaining their structural integrity.

Finally, their thermal shock stability is remarkable. They can withstand rapid temperature changes without damage. When the temperature changes from room temperature to 1200°C and then back to room temperature repeatedly, the strength loss of ordinary magnesia-chrome bricks is less than 10%, which is crucial for industries with frequent temperature fluctuations.

Metallurgy: In the steelmaking process, ordinary magnesia-chrome bricks are widely used in converters, electric arc furnaces, and ladles. Their high strength and corrosion resistance can effectively resist the erosion of high-temperature molten steel and slag, reducing the frequency of furnace lining repairs and replacements. According to statistics, using ordinary magnesia-chrome bricks can increase the furnace lining service life by 20 - 30% compared with some traditional materials, significantly reducing production costs.

Glass Manufacturing: In glass melting furnaces, ordinary magnesia-chrome bricks are used in areas such as the furnace crown, side walls, and throat. Their thermal shock stability and erosion resistance can ensure the stable operation of the furnace. For instance, in a large-scale glass manufacturing plant, after using ordinary magnesia-chrome bricks, the glass production yield increased by about 15% due to the more stable furnace environment, and the energy consumption was reduced by 10%.

| Properties | Ordinary Magnesia-Chrome Bricks | Traditional Magnesia Bricks |

|---|---|---|

| Compressive Strength (MPa) | 50 | 30 |

| Corrosion Rate (% per year) | < 5 | > 10 |

| Thermal Shock Stability (Strength Loss after repeated temperature changes) | < 10% | > 20% |

From the above comparison, it is clear that ordinary magnesia-chrome bricks have significant advantages over traditional magnesia bricks in terms of strength, corrosion resistance, and thermal shock stability.

A steelmaking company in Europe was facing frequent furnace lining replacements, which led to high production costs and production interruptions. After switching to ordinary magnesia-chrome bricks, the furnace lining service life increased from 6 months to 9 months, and the production efficiency increased by 18%. Another glass manufacturing company in Asia used ordinary magnesia-chrome bricks in its new melting furnace. As a result, the quality of the glass products improved, and the production cost was reduced by 12%.

If you are in the high-temperature industry and are looking for a reliable refractory material that can provide stable solutions, reduce costs, and improve efficiency, ordinary magnesia-chrome bricks are definitely worth considering. To learn more about how ordinary magnesia-chrome bricks can benefit your business, click here to explore further details.