The aluminum industry is facing significant challenges in sustainable development, primarily due to high energy consumption and substantial maintenance costs. According to industry statistics, aluminum smelting accounts for approximately 5% of global industrial electricity consumption. Moreover, the high-temperature and corrosive environment in aluminum electrolysis cells leads to frequent maintenance and replacement, increasing both time and financial costs for enterprises. These issues not only affect the economic efficiency of the industry but also pose challenges to environmental protection and resource conservation.

Vermiculite insulation boards are made from natural vermiculite through special processing. In the high - temperature environment of aluminum electrolysis cells, they can effectively adsorb and purify harmful gases and impurities, improving the purity of the electrolysis environment. For example, they can reduce the content of fluoride and other pollutants in the flue gas by about 30%, which is beneficial for both the health of workers and environmental protection.

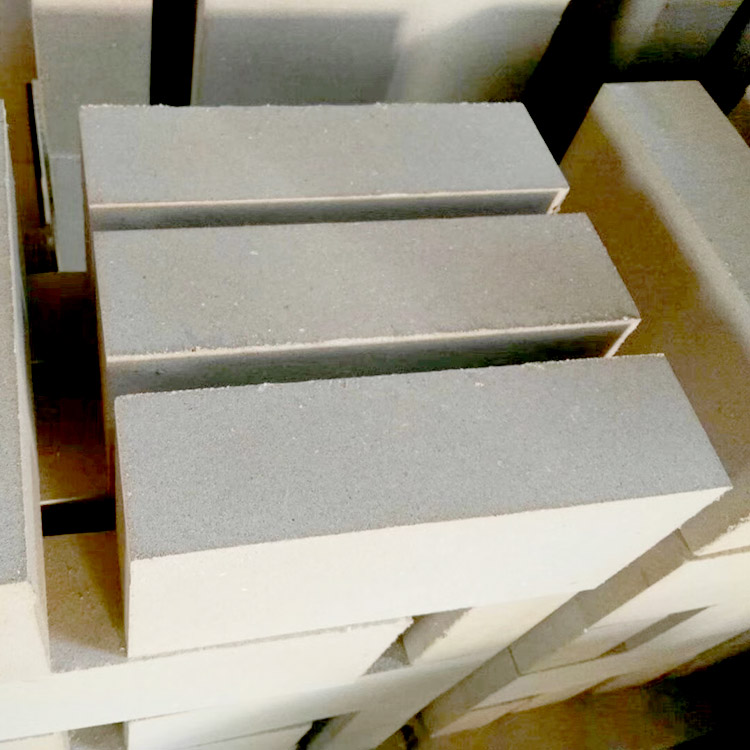

As the usage time increases, vermiculite insulation boards can gradually adapt to the high - temperature environment. Their internal structure becomes more stable, and their thermal insulation performance is further enhanced. Tests show that after six months of use, the thermal conductivity of vermiculite insulation boards can be reduced by about 15%, effectively reducing heat loss.

By providing excellent thermal insulation and corrosion resistance, vermiculite insulation boards can protect the inner lining of aluminum electrolysis cells. This reduces the damage caused by high - temperature and corrosive substances to the cell lining, thereby extending the service life of the cells. In some practical applications, the service life of aluminum cells using vermiculite insulation boards has been extended by about 2 - 3 years, significantly reducing the frequency of cell replacement and maintenance costs.

The outstanding thermal insulation performance of vermiculite insulation boards can effectively reduce heat loss in aluminum electrolysis cells. According to actual measurements, using vermiculite insulation boards can save about 10% - 15% of electricity consumption in aluminum smelting, which is a huge cost - saving for energy - intensive aluminum enterprises.

In a large - scale aluminum smelting enterprise in Australia, after replacing the original insulation materials with vermiculite insulation boards, the enterprise achieved remarkable results. The heat loss of the aluminum electrolysis cells was reduced by 12%, and the annual electricity cost was saved by about $500,000. At the same time, the maintenance cycle of the cells was extended from once a year to once every three years, greatly improving production efficiency and reducing production costs.

With the increasing global emphasis on environmental protection and sustainable development, the aluminum industry is also actively promoting green transformation. Vermiculite insulation boards, with their excellent energy - saving and environmental - friendly performance, are highly consistent with the development trend of the industry. In the future, as technology continues to improve, the performance of vermiculite insulation boards will be further enhanced, and their application scope will also be expanded.

Now, let's think about it. In the face of increasingly strict environmental regulations and rising energy costs, how can your enterprise better achieve energy - saving and emission - reduction goals? Is it time to consider the application of vermiculite insulation boards?