In the aluminum industry, electrolytic cells are at the heart of the production process. However, they face significant challenges such as high energy consumption and high maintenance costs. The choice of appropriate insulation materials is crucial for these cells to operate efficiently and sustainably. Vermiculite insulation boards have emerged as a promising solution, offering excellent high - temperature performance and energy - saving advantages.

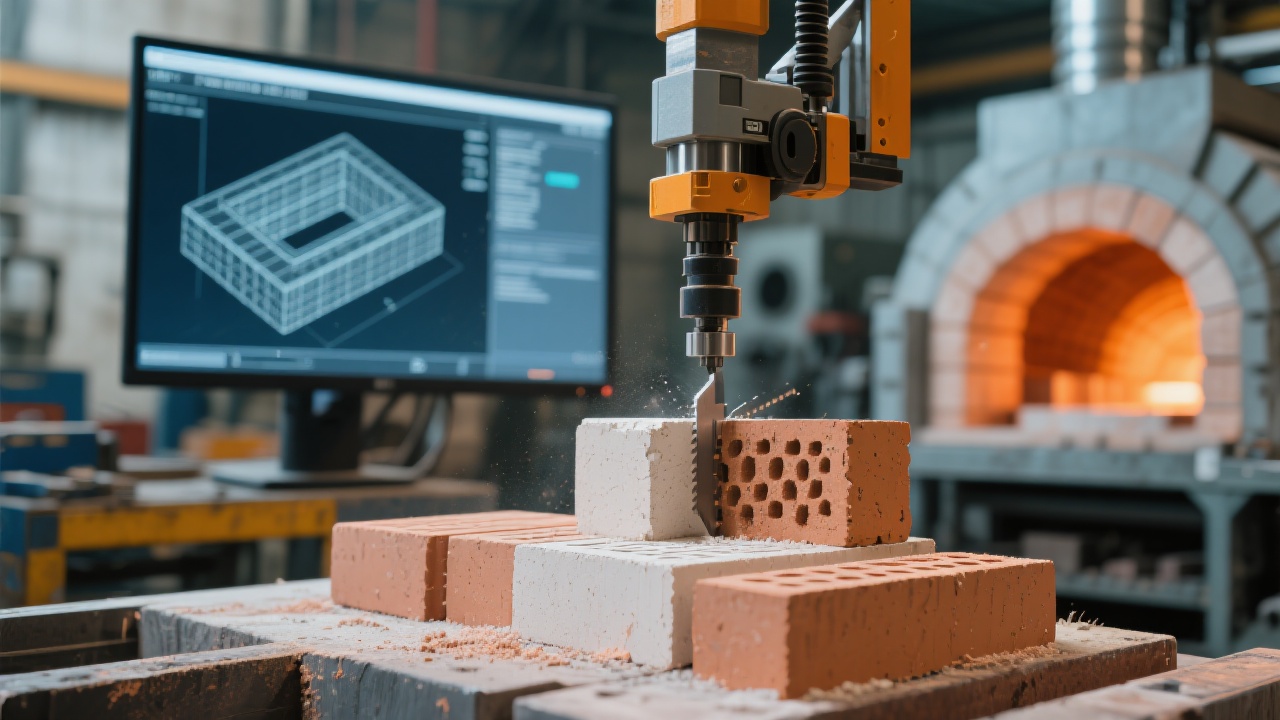

Vermiculite insulation boards are mainly composed of expanded vermiculite, a naturally occurring mineral. When heated, vermiculite expands into a worm - like structure, creating numerous tiny air pockets. These air pockets act as excellent insulators, providing high thermal resistance. Scientifically, the low thermal conductivity of air trapped in these pockets reduces the heat transfer rate according to Fourier's law of heat conduction.

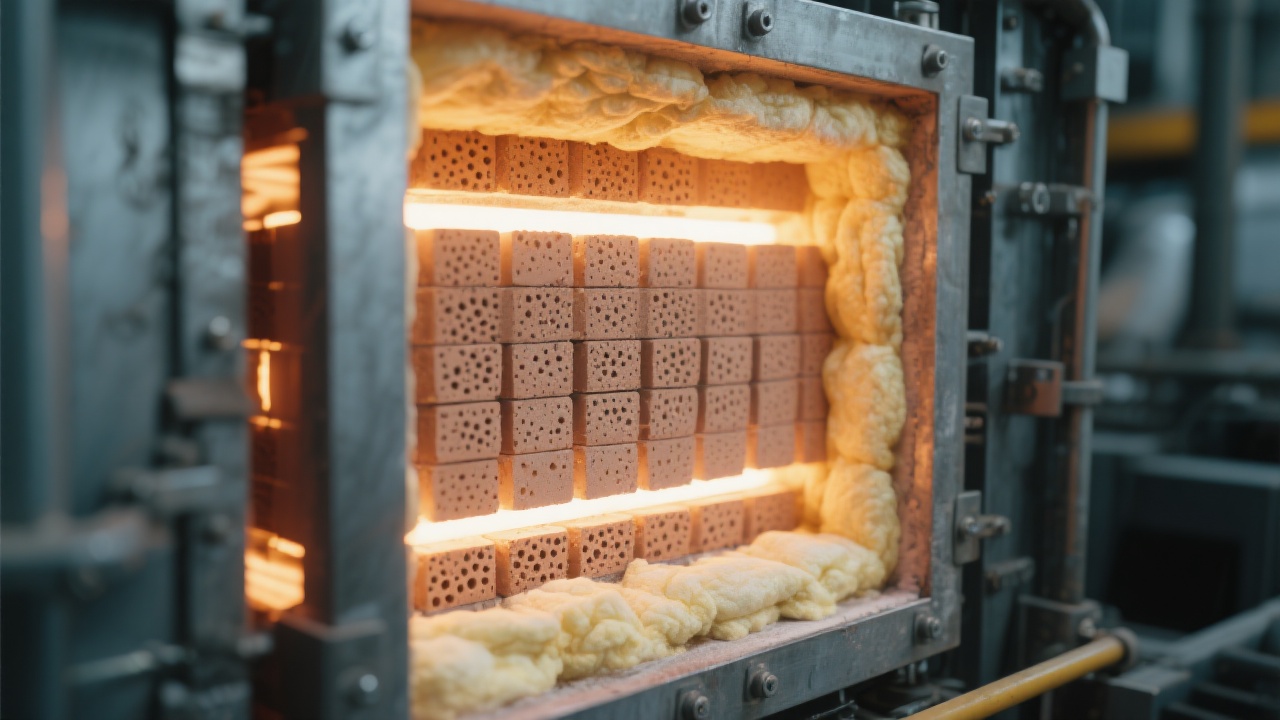

One of the most remarkable features of vermiculite insulation boards is their high - temperature resistance. They can withstand temperatures up to 1050°C. In addition, they have a unique self - purification mechanism for organic impurities at high temperatures. During the operation of the electrolytic cell, organic impurities may accumulate on the insulation material. Vermiculite insulation boards can break down these organic impurities at high temperatures, preventing them from corroding the insulation and the electrolytic cell itself.

When compared to traditional insulation materials, vermiculite insulation boards show significant advantages. Traditional insulation materials may have lower temperature resistance, which means they need to be replaced more frequently. In contrast, vermiculite insulation boards can significantly extend the service life of electrolytic cells. On average, using vermiculite insulation boards can extend the life of an electrolytic cell by 2 - 3 years compared to traditional materials.

In terms of maintenance, the self - purification mechanism of vermiculite insulation boards reduces the frequency of maintenance. Traditional insulation materials may require regular cleaning or replacement due to the accumulation of impurities, while vermiculite insulation boards can maintain their performance over a longer period. This reduces the overall maintenance cost by approximately 30%.

Heat loss is another critical factor. Vermiculite insulation boards can reduce heat loss by up to 25% compared to traditional insulation materials. This is mainly due to their low thermal conductivity and high - temperature stability. The reduction in heat loss directly translates into energy savings and lower production costs.

An aluminum smelting plant in Australia adopted vermiculite insulation boards for their electrolytic cells. Before the adoption, the plant had high energy consumption, with an annual electricity cost of about $500,000 for the electrolytic cell section. After installing vermiculite insulation boards, the energy consumption decreased by 20%, resulting in an annual cost savings of $100,000. In addition, the maintenance frequency decreased from once every 6 months to once a year, saving on labor and material costs.

Vermiculite insulation boards offer a series of advantages that are highly compatible with the needs of the aluminum industry. Their high - temperature resistance, self - purification mechanism, and energy - saving capabilities make them an ideal choice for electrolytic cell insulation. By using vermiculite insulation boards, aluminum industrial enterprises can achieve both efficient production and green energy - saving goals.

If you are an aluminum industrial enterprise facing high energy consumption and maintenance challenges, we encourage you to learn more about vermiculite insulation boards. Click here to find out how this high - performance insulation material can help you achieve efficient energy - saving and green production.

Do you have similar problems in your industry? Share your specific scenarios with us, and we'll send you 3 solution cases from the same industry.