In high-temperature industrial production, refractory materials often face issues such as erosion, thermal shock cracking, and unstable performance. Ordinary magnesite-chrome bricks have emerged as a reliable solution for high-temperature scenarios like glass furnaces, thanks to their high strength, excellent slag resistance, and outstanding thermal shock stability. This article delves into their core advantages, typical application scenarios, and performance improvements compared to magnesia bricks, aiming to help you reduce maintenance costs and ensure continuous production.

High-temperature industries, including glass manufacturing and metallurgy, rely heavily on refractory materials. However, these materials often encounter several challenges. For instance, refractory materials can be easily eroded by molten slag, which shortens their service life. Thermal shock cracking is another common problem, occurring when the material is exposed to rapid temperature changes. This can lead to structural damage and even equipment failure. Additionally, the performance of some refractory materials may become unstable over time, affecting the quality and efficiency of production.

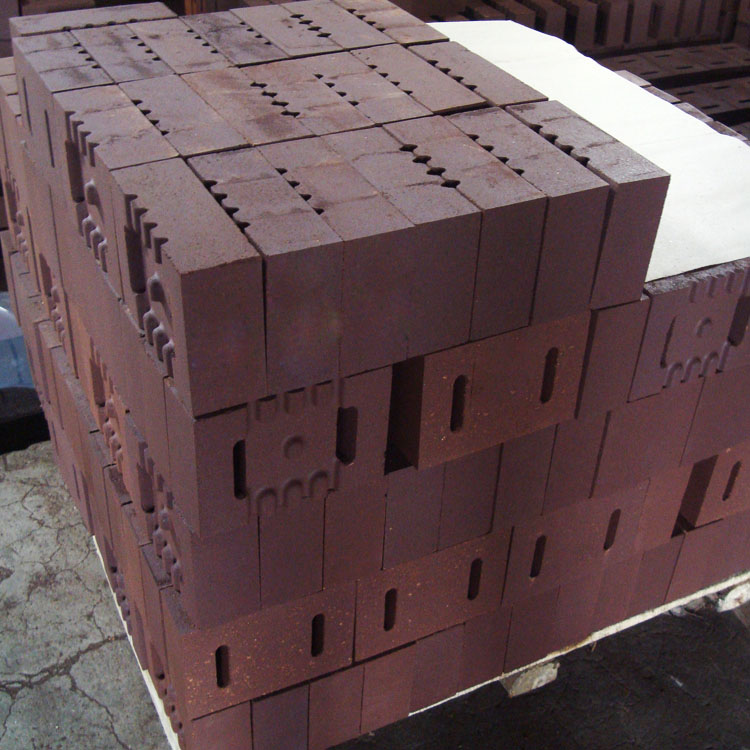

Ordinary magnesite-chrome bricks are composed of magnesium oxide (MgO) and chromium oxide (Cr₂O₃), which endow them with unique physical and chemical properties. The high content of MgO provides high strength and good refractoriness, making the bricks resistant to high temperatures. The addition of Cr₂O₃ enhances the anti - slag property, effectively preventing the penetration and erosion of molten slag. Moreover, the special crystal structure of these bricks gives them excellent thermal shock stability, allowing them to withstand rapid temperature changes without cracking.

For example, in a glass furnace, the high strength of ordinary magnesite-chrome bricks can support the weight of the furnace structure, while the anti - slag property protects the bricks from the corrosive effect of molten glass. The thermal shock stability ensures that the bricks can maintain their integrity during the heating and cooling cycles of the furnace, reducing the risk of damage and replacement.

In the glass manufacturing industry, ordinary magnesite-chrome bricks are widely used in the key parts of glass furnaces, such as the melting zone and the throat. In a large - scale glass production plant, after replacing the original refractory materials with ordinary magnesite-chrome bricks, the service life of the furnace lining was extended by up to 30%. This not only reduced the frequency of furnace repairs but also increased the production efficiency by minimizing the downtime for maintenance.

In the metallurgical industry, these bricks are used in steelmaking converters and electric arc furnaces. They can effectively resist the high - temperature molten steel and slag, improving the overall performance of the furnace. A steel mill reported that using ordinary magnesite-chrome bricks reduced the slag erosion rate by 20%, which significantly lowered the maintenance cost and improved the quality of steel products.

| Properties | Ordinary Magnesite-Chrome Bricks | Magnesia Bricks |

|---|---|---|

| Strength | High, can withstand heavy loads | Relatively lower, may be prone to cracking under heavy loads |

| Anti - slag Property | Excellent, can resist penetration and erosion of molten slag | Good, but not as effective as magnesite-chrome bricks |

| Thermal Shock Stability | Outstanding, can withstand rapid temperature changes | Average, may crack under rapid temperature changes |

One customer from a glass manufacturing company said, "Since we started using ordinary magnesite-chrome bricks in our glass furnaces, we have noticed a significant improvement in the stability of our production process. The reduced downtime has allowed us to increase our output and improve the quality of our glass products. We are very satisfied with the performance of these bricks."

By choosing ordinary magnesite-chrome bricks, you can reduce maintenance costs, increase production efficiency, and ensure the stable operation of your high - temperature equipment. If you want to learn more about these excellent refractory materials or obtain technical data, please click here to get in touch with us. Let our ordinary magnesite-chrome bricks bring you a more reliable and efficient high - temperature industrial solution!