As industries continue to evolve, the demand for high-performance refractory materials has never been higher. Among the many options available, silicon nitride bonded silicon carbide bricks have emerged as a preferred choice for their exceptional strength, thermal conductivity, and durability. These advanced refractories are widely used in the non-ferrous mining, metallurgical blast furnaces, and ceramic industries, where reliability and efficiency are paramount.

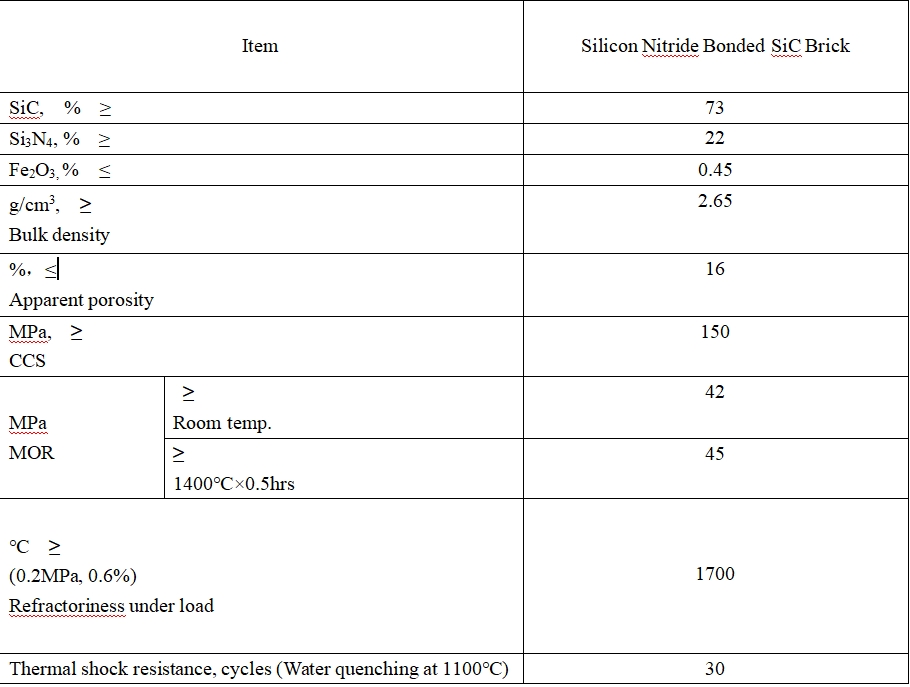

Silicon nitride bonded silicon carbide bricks are known for their superior mechanical strength, resistance to thermal shock, and excellent heat transfer capabilities. These properties make them ideal for high-temperature environments where traditional refractories may degrade or fail. According to independent laboratory tests conducted by third-party certification bodies, the product consistently meets and exceeds international standards for performance and quality.

With a thermal conductivity of up to 18 W/m·K, these bricks ensure efficient heat distribution and reduce energy consumption in industrial processes. Their compressive strength is rated at over 400 MPa, making them highly resistant to wear and tear under extreme conditions.

The journey of silicon nitride bonded silicon carbide bricks from a niche product to a globally recognized solution has been marked by steady growth and customer trust. Over the past decade, the product has gained the confidence of more than 20 leading companies across Europe, North America, and Asia. Today, over 80% of the production volume is exported to more than 15 countries and regions, including the United States, Germany, and Japan.

One of the most notable success stories comes from a major European smelting company that switched to silicon nitride bonded silicon carbide bricks for its high-temperature furnace lining. After six months of operation, the company reported a 15% reduction in maintenance costs and a 10% improvement in energy efficiency. The client praised the product’s consistent performance and long service life, which significantly reduced downtime and operational costs.

Another case involves a large Chinese non-ferrous metal producer that adopted the product for its melting and refining operations. The company saw a noticeable improvement in product quality and process stability. The feedback from their engineering team highlighted the material’s ability to withstand harsh conditions without degradation, even after extended use.

| Region | Export Volume (tons/year) | Customer Base |

|---|---|---|

| Europe | 1,200 | 12 major smelters and foundries |

| North America | 950 | 8 large industrial clients |

| Asia | 700 | 6 key manufacturers |

With years of experience in manufacturing and exporting high-quality refractory materials, our company has built a strong reputation for delivering reliable solutions that meet the needs of global customers. We offer customized options to suit different applications, ensuring optimal performance in various industrial settings.

Our products are not only trusted by international clients but also supported by comprehensive technical assistance and after-sales services. Whether you're looking to enhance your furnace efficiency or reduce maintenance costs, we provide the expertise and support needed to achieve your goals.