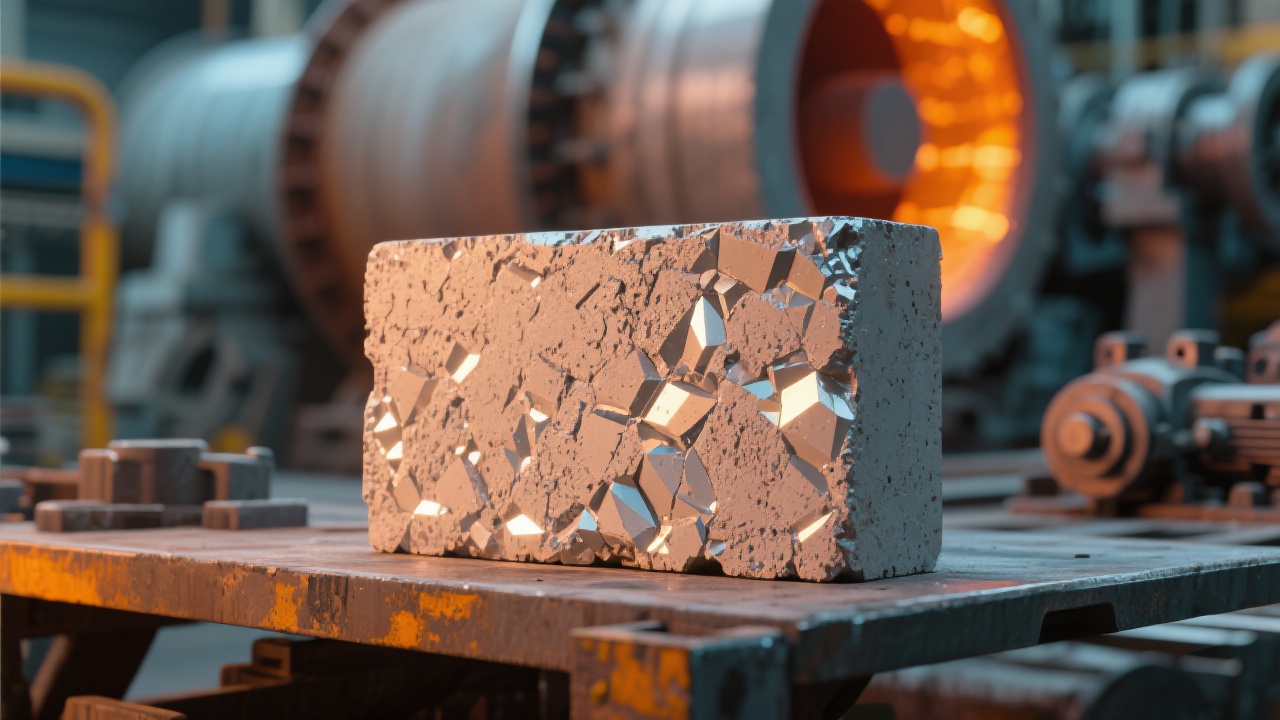

For manufacturers seeking to reduce energy costs, boost throughput, and strengthen market positioning—the choice of refractory materials matters more than ever. Traditional silicon bricks often fall short in thermal conductivity, leading to uneven heat distribution, longer heating cycles, and increased fuel consumption. But what if your kiln could run 15–20% faster while using less energy?

Our high-conductivity silicon brick isn’t just an upgrade—it’s a structural revolution. By refining crystal orientation and reducing average pore diameter from 12 μm (standard) to just 4 μm, we’ve achieved a remarkable 38% improvement in thermal conductivity (measured at 3.2 W/m·K vs. 2.3 W/m·K for conventional types).

| Property | Standard Silicon Brick | High-Conductivity Version |

|---|---|---|

| Thermal Conductivity (W/m·K) | 2.3 | 3.2 |

| Average Pore Size (μm) | 12 | 4 |

| Energy Savings per Batch | ~7% | ~18% |

In real-world applications across ceramic, glass, and metal industries, this translates into tangible ROI: one European tile manufacturer reduced annual gas costs by €42,000 after switching to our solution—a change that paid for itself within 11 months.

It’s not just about specs—it’s about results. In a recent case study with a U.S.-based steel furnace operator, implementing our high-conductivity bricks led to:

These improvements don't just help margins—they build trust with clients who demand consistent quality and sustainable operations.

As global regulations tighten around carbon emissions and energy efficiency, forward-thinking producers are turning to smarter material choices—not just for compliance, but for competitive advantage.

If you're managing production lines where every minute counts and every watt matters, it's time to ask: Are your refractories holding you back—or setting you ahead?

Ready to transform your production efficiency and reduce operational costs?

Download Our Free Case Study & Request a Sample