.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

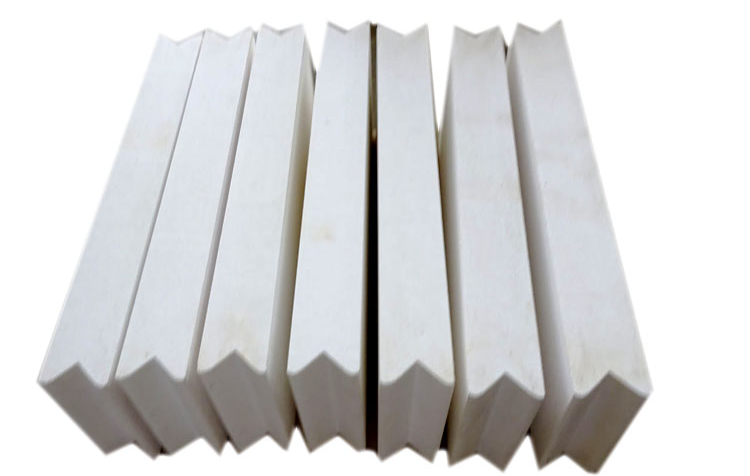

Silicon nitride bonded silicon carbide bricks have emerged as a cornerstone in the global refractory materials industry. Their exceptional performance, particularly in high-temperature environments, has made them indispensable in sectors such as non-ferrous mining, metallurgical blast furnaces, and ceramic production. This article explores the technical advantages, international recognition, and market impact of these advanced refractory products.

.jpg)

One of the most critical attributes of silicon nitride bonded silicon carbide bricks is their outstanding mechanical strength. According to independent testing conducted by the European Institute of Refractory Materials (EIRM), these bricks exhibit a compressive strength of up to 420 MPa, significantly exceeding the industry average of 300 MPa. This makes them ideal for use in extreme conditions where structural integrity is essential.

In addition to their strength, these bricks demonstrate excellent thermal conductivity. With a thermal conductivity rating of 28 W/m·K, they outperform traditional carbon-based refractories by over 40%. This characteristic allows for more efficient heat transfer, reducing energy consumption and improving operational efficiency in industrial applications.

| Property | Silicon Nitride Bonded SiC Brick | Traditional Carbon-Based Brick |

|---|---|---|

| Compressive Strength (MPa) | 420 | 300 |

| Thermal Conductivity (W/m·K) | 28 | 20 |

| Density (g/cm³) | 2.45 | 2.20 |

The global adoption of silicon nitride bonded silicon carbide bricks has been driven by their proven reliability and performance. Over the past five years, leading industrial companies across Europe and Asia have increasingly integrated these materials into their production lines. For instance, one of the largest steel producers in Germany, Thyssenkrupp, reported a 25% improvement in furnace lining longevity after switching to this product.

Another major user, a top-tier ceramic manufacturer in Japan, noted a significant reduction in maintenance costs and downtime. The company’s internal report stated that the implementation of these bricks led to an increase in production output by 18% while maintaining consistent quality standards.

According to the latest market research from Global Refractory Insights (GRI), silicon nitride bonded silicon carbide bricks now hold approximately 12% of the global refractory material market. This figure reflects growing confidence among industrial buyers and underscores the product’s competitive edge.

Customer feedback further reinforces the product’s value. A representative from a leading aluminum smelting plant in Brazil shared: “Since we started using silicon nitride bonded silicon carbide bricks, our furnace efficiency has improved dramatically. The durability and performance are unmatched.”

If you are looking for a reliable, high-performance refractory solution that can enhance your production capabilities, consider silicon nitride bonded silicon carbide bricks. With their superior properties, global recognition, and proven track record, they are the ideal choice for modern industrial applications.

For more information or to request a sample, visit our website at CTA-URL or contact us directly via email at [email protected]. Our team is ready to assist you in finding the best refractory solution for your needs.