In high-temperature industrial settings such as metallurgy and glass manufacturing, magnesia-chrome bricks play a crucial role. These bricks are designed to withstand extreme temperatures and harsh chemical environments, ensuring the smooth operation of industrial furnaces and kilns. Traditional methods of manufacturing magnesia-chrome bricks have evolved over time, leading to the development of different types of products.

Traditional magnesia-chrome bricks are typically produced through two main methods: firing and non-firing. Unfired magnesia-chrome bricks are made by pressing raw materials together without high-temperature firing. They are relatively inexpensive to produce and have certain corrosion resistance. However, they have limitations. For example, their strength at high temperatures is relatively low, with a compressive strength of about 30 - 40 MPa, and they may experience significant shrinkage after long-term use, leading to gaps in the furnace lining and reducing the overall performance of the furnace.

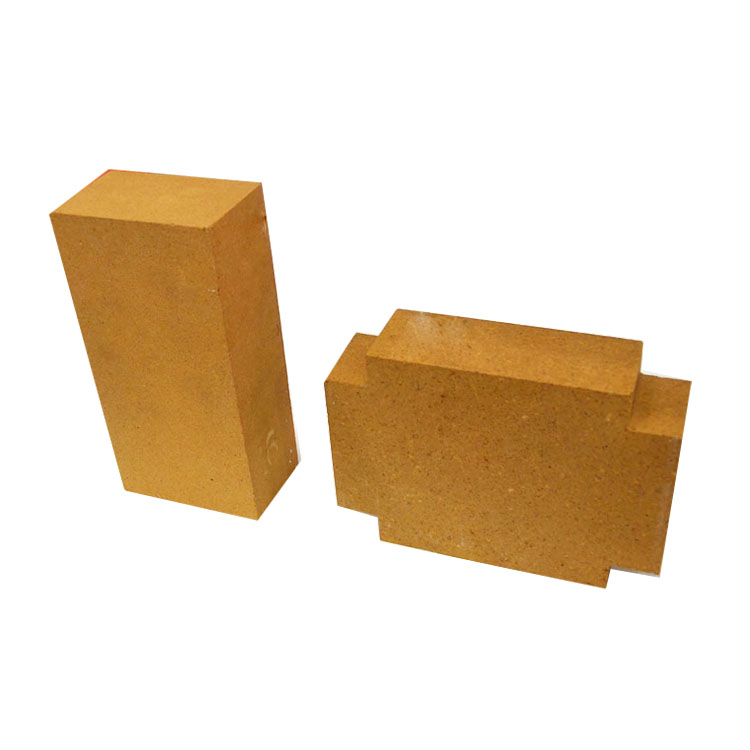

Directly bonded magnesia-chrome bricks are produced through high-temperature firing, which forms a direct bond between the magnesia and chrome components. This results in several significant advantages. Firstly, they have high strength at high temperatures, with a compressive strength of up to 60 - 80 MPa. Secondly, they have excellent thermal shock resistance, being able to withstand rapid temperature changes without cracking. Thirdly, their corrosion resistance is superior, which can effectively resist the erosion of various slags and molten metals. Compared with unfired magnesia-chrome bricks, directly bonded magnesia-chrome bricks can extend the service life of the furnace lining by about 30% - 50%.

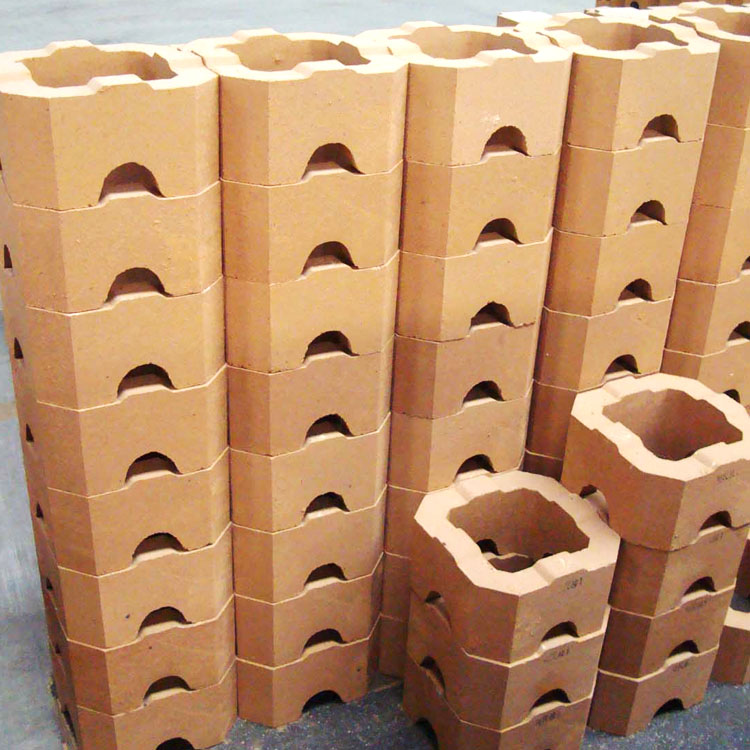

Directly bonded magnesia-chrome bricks are widely used in various high-temperature industries. In the metallurgical industry, they are used in steelmaking converters, electric arc furnaces, and ladles. In the glass industry, they are used in glass melting furnaces. Their high performance ensures the stability of the production process and improves the quality of the final products.

A steel manufacturing company in Europe replaced its unfired magnesia-chrome bricks with directly bonded magnesia-chrome bricks in its electric arc furnace. After the replacement, the furnace lining's service life increased from 300 heats to 450 heats, an increase of 50%. At the same time, the maintenance cost was reduced by about 20% due to less frequent repairs and replacements. Another glass manufacturing company in Asia also reported significant improvements in production efficiency and product quality after using directly bonded magnesia-chrome bricks in its melting furnace.

In conclusion, directly bonded magnesia-chrome bricks are an ideal choice for enterprises to enhance their competitiveness. With their high strength, excellent thermal shock resistance, and superior corrosion resistance, they can effectively reduce production costs and improve production efficiency. If you are looking for a high-quality refractory material to optimize your high-temperature production process, don't miss directly bonded magnesia-chrome bricks.

Contact us now to learn more about directly bonded magnesia-chrome bricks and how they can benefit your business. Our experts are ready to provide you with detailed solutions and support!