As a leading supplier of advanced refractory materials, our silicon nitride bonded silicon carbide bricks have become a preferred choice for global industrial leaders. With their superior mechanical strength, excellent thermal conductivity, and long service life, these bricks are widely used in the non-ferrous mining and metallurgy industries.

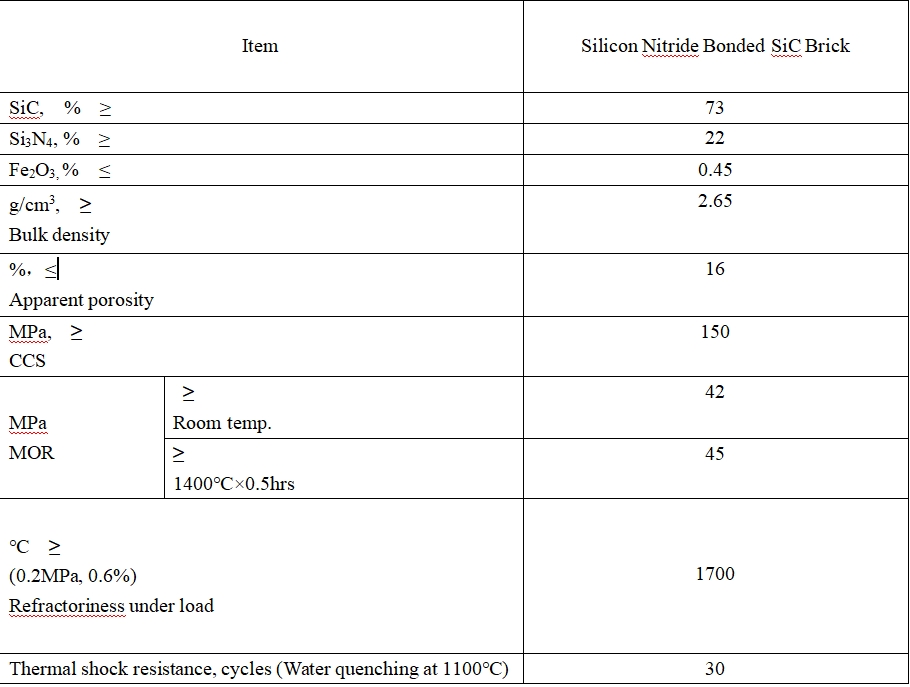

Our silicon nitride bonded silicon carbide bricks are engineered to withstand extreme temperatures and harsh environments. Through rigorous testing by independent laboratories, we have confirmed that the material has a compressive strength of up to 450 MPa, a thermal conductivity of 28 W/m·K, and a low porosity of less than 12%. These properties make it ideal for high-temperature applications such as smelting furnaces and ladles.

The journey of gaining international recognition began with a small but ambitious project in Southeast Asia. A major copper smelting plant was facing frequent lining failures due to the aggressive nature of molten slag. Our team provided customized solutions using silicon nitride bonded silicon carbide bricks, which significantly reduced maintenance downtime and extended the furnace's operational life. This success led to word-of-mouth referrals across the industry.

Soon after, we received orders from several multinational corporations in Europe, North America, and the Middle East. These companies, known for their strict quality standards, conducted extensive evaluations before finalizing their contracts. The results were impressive — our products not only met but exceeded their expectations.

.jpg)

Over the past five years, more than 15 major international companies have adopted our silicon nitride bonded silicon carbide bricks. Among them is a leading aluminum producer in Germany, which reported a 30% reduction in energy consumption after switching to our product. Another customer, a large zinc smelter in Chile, shared that the service life of their furnace linings increased by nearly 50%.

| Region | Countries Served | Market Share |

|---|---|---|

| Europe | 8 | 22% |

| Asia | 12 | 35% |

| Americas | 7 | 20% |

| Middle East & Africa | 5 | 15% |

Currently, over 80% of our production is exported to more than 30 countries worldwide. In the last fiscal year, our sales reached $18 million, with a growth rate of 25% compared to the previous year. This reflects the growing demand for high-performance refractory materials in the global market.

We invite you to explore how our silicon nitride bonded silicon carbide bricks can enhance your production efficiency and reduce operational costs. Whether you're looking to upgrade your current refractory system or seeking a reliable partner for future projects, we are here to support you every step of the way.