.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

As one of the most critical components in high-temperature industrial processes, refractory materials play a vital role in ensuring operational efficiency, safety, and longevity of equipment. Among these, nitride-bonded silicon carbide bricks have emerged as a preferred choice for their exceptional performance and reliability in demanding environments.

In recent years, the demand for high-performance refractories has surged across industries such as steelmaking, glass manufacturing, and cement production. These industries require materials that can withstand extreme temperatures, resist thermal shock, and maintain structural integrity over long periods. Nitride-bonded silicon carbide bricks meet these requirements with remarkable properties, making them a key player in the global refractory market.

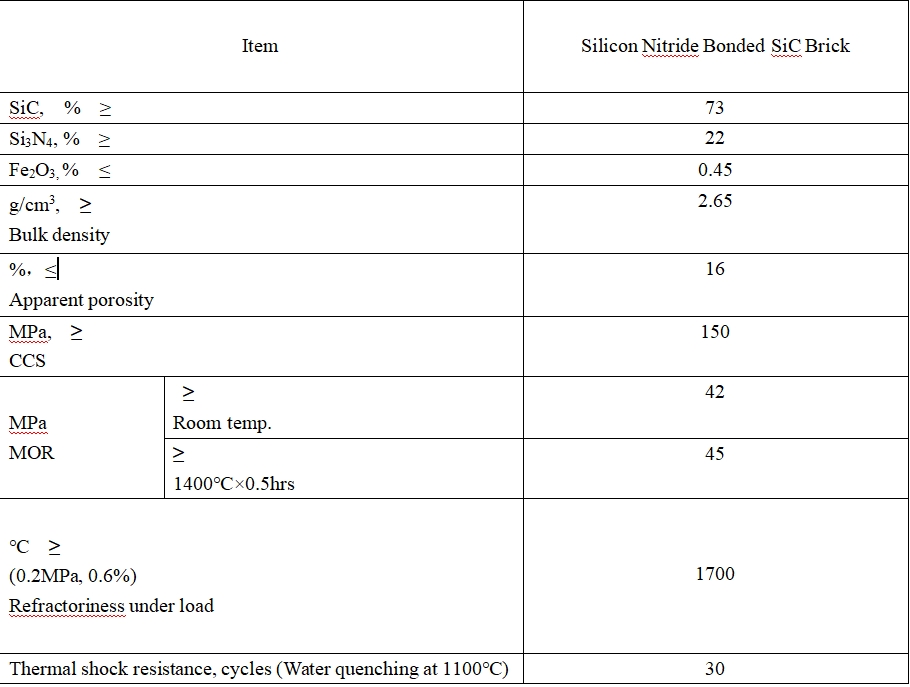

Nitride-bonded silicon carbide bricks are known for their outstanding mechanical strength, thermal conductivity, and chemical resistance. According to independent laboratory tests conducted by the European Refractory Testing Institute (ERTI), these bricks demonstrate:

The superior performance of nitride-bonded silicon carbide bricks is further supported by their low coefficient of thermal expansion, which minimizes cracking and deformation under repeated heating and cooling cycles. This makes them ideal for applications in coke ovens, glass furnaces, and high-temperature kilns.

.jpg)

The journey of nitride-bonded silicon carbide bricks toward international recognition began with rigorous testing and certification by leading industry bodies. In 2018, the product received ISO 9001 and EN 1367 certifications, marking its compliance with global quality standards. Since then, it has been widely adopted by major industrial players in Europe and North America.

A notable example is the collaboration with a leading steel producer in Germany, where the use of nitride-bonded silicon carbide bricks in blast furnace linings resulted in a 20% reduction in maintenance downtime and a 15% increase in energy efficiency. The company’s technical director commented:

“Nitride-bonded silicon carbide bricks have significantly improved our operational efficiency and reduced long-term costs. Their performance is unmatched in our production environment.”

Today, more than 80% of the production volume is exported to over 15 countries, including the United States, Germany, France, and the UK. The consistent quality and performance have made this product a trusted name among international buyers.

Several large-scale industrial projects have successfully implemented nitride-bonded silicon carbide bricks, with positive feedback from end-users. For instance, a glass manufacturing plant in the Netherlands reported a 30% improvement in furnace lining lifespan after switching to this material. Another case involves a cement kiln in the US, where the bricks demonstrated excellent resistance to thermal stress and chemical erosion.

These real-world applications not only validate the product's performance but also highlight its adaptability to diverse industrial settings. Whether in high-temperature processing or continuous operation, nitride-bonded silicon carbide bricks deliver consistent results.

.jpg)

With a proven track record in the European and American markets, our nitride-bonded silicon carbide bricks offer:

Our commitment to innovation, quality control, and customer satisfaction ensures that every brick meets the highest performance expectations.

If you're looking for a reliable and high-performing refractory solution for your industrial operations, we invite you to explore how our nitride-bonded silicon carbide bricks can benefit your business. Contact us today to learn more about our products and services.

Explore More and Request a Sample