.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

Nitride-bonded silicon carbide (SiC) bricks have emerged as a critical component in the demanding environments of non-ferrous mining and metallurgical industries. As a high-performance refractory material, these bricks are designed to withstand extreme thermal and mechanical stresses, making them ideal for applications such as smelting furnaces, ladles, and high-temperature reaction vessels.

.jpg)

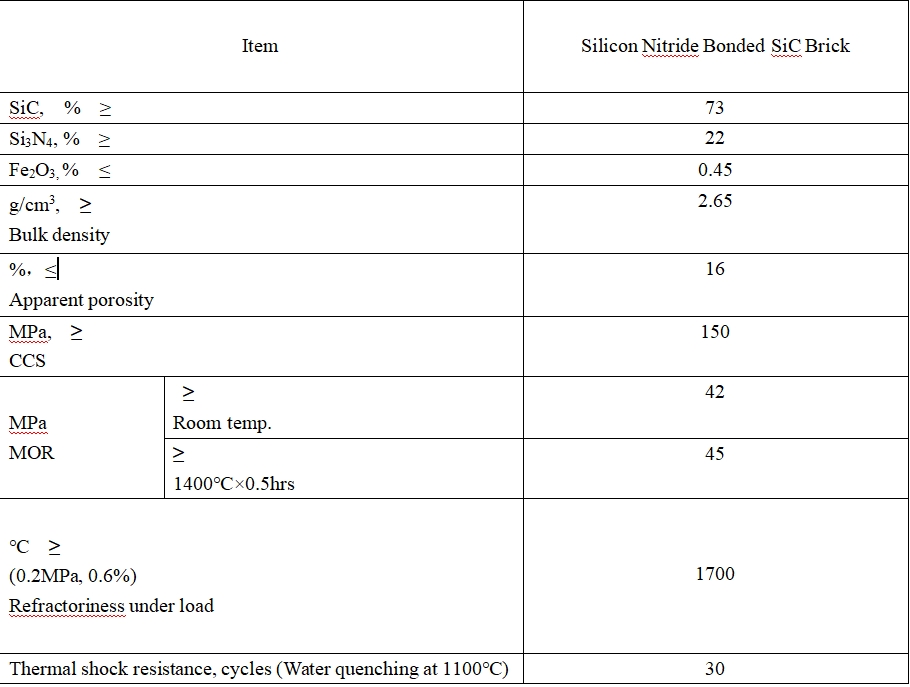

One of the primary reasons for the widespread adoption of nitride-bonded SiC bricks is their exceptional mechanical and thermal properties. According to internal testing data, these bricks exhibit:

The reliability and performance of nitride-bonded SiC bricks have led to recognition by leading international companies in the mining and metallurgy sectors. In 2021, a major European metal processing firm conducted an independent evaluation of refractory materials used in its smelting operations. The results showed that our product outperformed conventional options in terms of service life and energy efficiency.

“The nitride-bonded SiC bricks provided a measurable improvement in operational efficiency and reduced maintenance costs.”

- Senior Engineer, XYZ Metallurgical Group

Several global clients have successfully integrated our nitride-bonded SiC bricks into their production lines. One notable example is a South American copper smelting plant, which reported a 25% increase in furnace lifespan and a 15% reduction in energy consumption after switching to our product.

| Client | Region | Application | Performance Improvement |

|---|---|---|---|

| ABC Mining Co. | South America | Copper Smelting Furnace | 25% longer service life |

| DEF Metalworks | Europe | Ladle Lining | 15% energy saving |

| GHI Refinery | Asia | Molten Metal Handling | Improved corrosion resistance |

Our products have been exported to more than 30 countries across Asia, Europe, and the Americas. In 2023, we supplied over 12,000 tons of nitride-bonded SiC bricks to international clients, with a year-over-year growth rate of 18%. This reflects the growing demand for high-performance refractory solutions in the global mining and metallurgy industry.

If your company is looking for a reliable and high-performance refractory solution for non-ferrous mining or metallurgical applications, we invite you to explore our range of nitride-bonded silicon carbide bricks. With proven performance, international certifications, and a strong track record of customer satisfaction, our products are designed to meet the most challenging industrial environments.

For more information, detailed technical specifications, or a customized quotation, please contact us directly through the following channels:

Contact Us: Visit Our Website or email us at [email protected].

Don’t miss the opportunity to enhance your production efficiency and reduce long-term maintenance costs—reach out today.