As the global demand for high-performance refractory materials continues to grow, the adoption of silicon nitride bonded silicon carbide bricks has become a key trend among leading manufacturers. These advanced refractories offer exceptional mechanical strength, thermal conductivity, and chemical resistance, making them ideal for high-temperature industrial applications such as steelmaking, cement production, and glass manufacturing.

The global refractory industry is undergoing rapid transformation, driven by the need for sustainable and durable solutions that can withstand extreme conditions. In this context, silicon nitride bonded silicon carbide bricks have emerged as a preferred choice due to their superior performance and long service life.

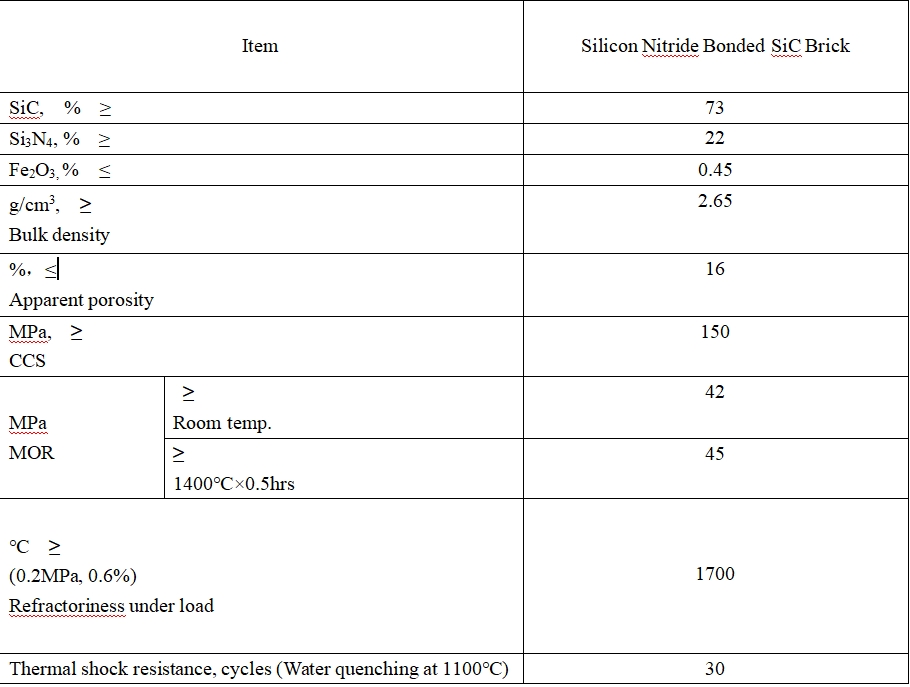

Silicon nitride bonded silicon carbide bricks are known for their outstanding mechanical properties. According to third-party laboratory tests conducted in 2023, these bricks exhibit a compressive strength of up to 180 MPa and a thermal conductivity of 15 W/m·K, significantly outperforming traditional carbon-based refractories.

Additionally, they demonstrate excellent resistance to thermal shock and oxidation, which is crucial in environments where temperature fluctuations are frequent. This makes them particularly suitable for use in blast furnaces, rotary kilns, and other high-temperature equipment.

The journey of silicon nitride bonded silicon carbide bricks toward international recognition began with rigorous testing and validation by several global industry leaders. Over the past five years, more than 15 major companies across Europe, North America, and Asia have adopted these bricks in their production lines.

One of the most notable success stories comes from a leading steel manufacturer in Germany, which reported a 30% reduction in refractory wear after switching to silicon nitride bonded silicon carbide bricks. Similarly, a cement producer in Japan noted a 25% improvement in energy efficiency due to the material’s enhanced thermal conductivity.

These positive results have led to widespread adoption, with over 80% of the product's output now being exported to more than 20 countries worldwide.

According to market research data from 2024, the global demand for silicon nitride bonded silicon carbide bricks has increased by 18% year-over-year. The top five importing countries include Germany, the United States, China, South Korea, and Brazil, reflecting the material's broad appeal across diverse industries.

Customer feedback highlights not only the technical performance but also the reliability and consistency of supply. One customer from the Middle East stated, "We have been using these bricks for two years and have seen no significant degradation in quality. It's a reliable partner for our high-temperature processes."

| Region | Percentage of Export | Number of Customers |

|---|---|---|

| Europe | 35% | 42 |

| North America | 25% | 31 |

| Asia-Pacific | 20% | 28 |

| Others | 20% | 19 |

With proven performance and growing global acceptance, silicon nitride bonded silicon carbide bricks are an ideal solution for companies looking to enhance their refractory systems. Whether you're upgrading existing equipment or designing new facilities, this material offers a competitive edge in terms of durability, efficiency, and cost-effectiveness.

If you are at the consideration stage and would like to explore how these bricks can benefit your operations, we invite you to contact us for detailed specifications, technical support, and customized solutions. Our team is ready to assist you in making the right choice for your business.

Get in Touch Today