In recent years, the aluminum industry has been facing increasing pressure to achieve sustainable development. With the rising costs of energy and raw materials, as well as stricter environmental regulations, aluminum manufacturers are constantly seeking ways to optimize production efficiency and reduce environmental impact. One of the key areas of focus is the selection and application of high - performance insulation materials.

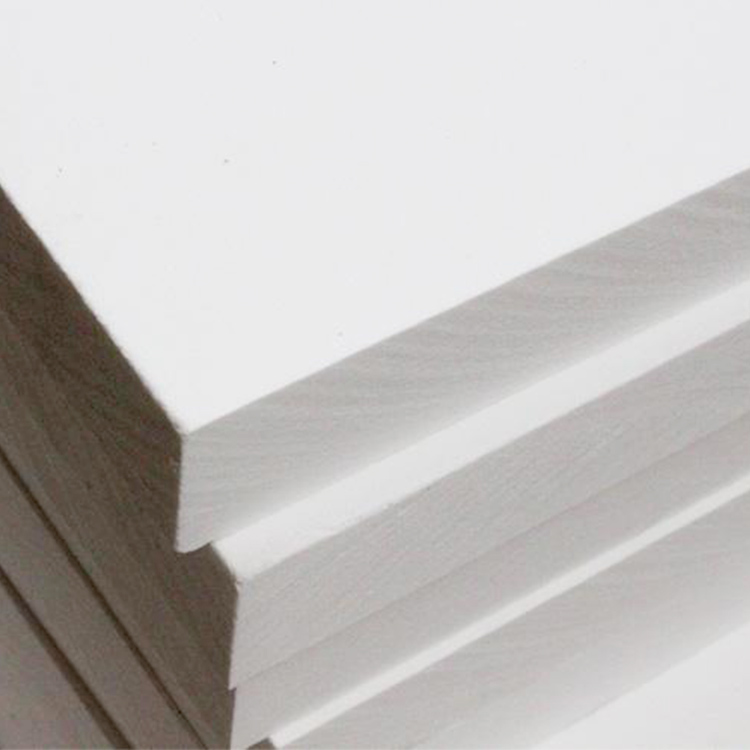

Vermiculite insulation boards have excellent high - temperature purification capabilities. In the high - temperature environment of aluminum production, they can effectively adsorb and remove impurities in the molten aluminum, improving the purity of the final product. According to industry experts, in some aluminum smelting plants, the use of vermiculite insulation boards has increased the purity of aluminum products by up to 2%.

Unlike some traditional insulation materials, the performance of vermiculite insulation boards improves over time. As they are exposed to high - temperature environments, their internal structure becomes more stable, which further enhances their insulation and other performance indicators. For example, after continuous use for 6 months in an aluminum production line, the thermal conductivity of vermiculite insulation boards can be reduced by about 10% compared to the initial state.

Vermiculite insulation boards can significantly extend the service life of aluminum troughs. By providing a stable thermal environment, they reduce the thermal stress on the troughs, which in turn reduces the frequency of repairs and replacements. In a real - world case, an aluminum plant in the United States reported that after using vermiculite insulation boards, the maintenance cycle of their aluminum troughs was extended from 1 year to 1.5 years, saving approximately 30% in maintenance costs.

Energy saving is one of the most significant advantages of vermiculite insulation boards. Their low thermal conductivity helps to reduce heat loss during the aluminum production process. Industry data shows that using vermiculite insulation boards can save up to 15% of energy consumption in aluminum smelting. Additionally, they have strong erosion resistance, which can withstand the corrosion of molten aluminum and other chemical substances, ensuring long - term stable performance.

Let's take a large - scale aluminum smelting enterprise in China as an example. Before using vermiculite insulation boards, the enterprise faced high energy consumption and frequent maintenance of aluminum troughs. After replacing the traditional insulation materials with vermiculite insulation boards, they achieved a 12% reduction in energy consumption and a 25% reduction in maintenance costs within one year. At the same time, the purity of their aluminum products also increased, which improved their market competitiveness.

In the context of the current industry's energy - saving and environmental - protection trends, vermiculite insulation boards play a crucial role in promoting the green development of the aluminum industry. They not only help enterprises reduce costs and improve efficiency but also contribute to the overall environmental protection goals of the industry. As the demand for sustainable development in the aluminum industry continues to grow, the application of vermiculite insulation boards will become more and more widespread.

Now, let's think about this: How can your aluminum enterprise better utilize the advantages of vermiculite insulation boards to achieve sustainable development? If you are an aluminum industry decision - maker or technician, don't miss this opportunity to optimize your production process. Click here to learn more about how vermiculite insulation boards can transform your aluminum production!