.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

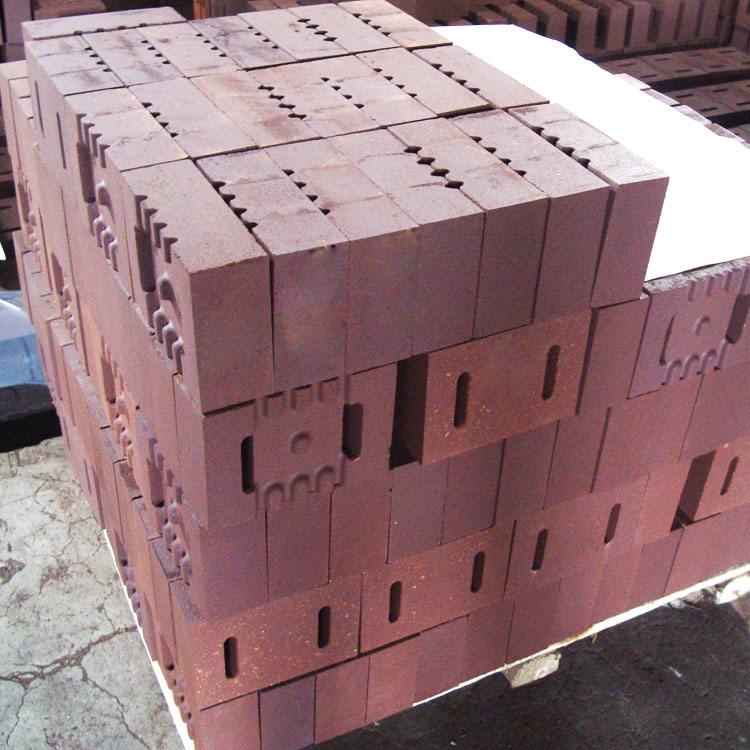

In the realm of refractory materials, magnesia-chrome bricks have long been a staple due to their excellent resistance to high temperatures and chemical corrosion. This article aims to conduct a thorough comparative analysis between directly bonded magnesia-chrome bricks and unfired magnesia-chrome bricks, providing global buyers with valuable insights to make informed decisions.

Traditionally, magnesia-chrome bricks are manufactured by mixing magnesia and chrome ore, followed by high-temperature firing. Unfired magnesia-chrome bricks, on the other hand, are produced by cold pressing the raw materials with the addition of binders. These unfired bricks offer the advantage of being more cost - effective and easier to produce in the short term. However, they often have limitations in terms of high - temperature strength and long - term stability. For example, unfired bricks may experience a strength loss of up to 20% at temperatures above 1200°C, which can be a significant drawback in high - temperature industrial applications.

Directly bonded magnesia-chrome bricks are produced through high - temperature sintering, which results in a direct bond between the magnesia and chrome components. This manufacturing process gives these bricks several outstanding properties. One of the most significant advantages is their high - temperature strength. Tests have shown that directly bonded magnesia-chrome bricks can maintain over 90% of their room - temperature strength at temperatures up to 1600°C. This high strength allows them to withstand the mechanical stress and thermal shock in high - temperature environments.

In addition to high - temperature strength, directly bonded magnesia-chrome bricks also have excellent chemical stability. They are highly resistant to corrosion from slag, molten metals, and alkaline substances. This makes them an ideal choice for industries that require long - term stability in harsh chemical environments.

In the metallurgical industry, directly bonded magnesia-chrome bricks are widely used in steelmaking converters, electric arc furnaces, and ladles. In steelmaking converters, where temperatures can reach up to 1700°C and the bricks are constantly exposed to molten steel and slag, the high - temperature strength and chemical resistance of directly bonded magnesia-chrome bricks ensure a longer service life. In the glass industry, these bricks are used in glass melting furnaces. The high - temperature stability of the bricks helps to maintain the shape and integrity of the furnace, ensuring the quality of the glass products.

A well - known steel manufacturer in Europe replaced the unfired magnesia-chrome bricks in their electric arc furnace with directly bonded magnesia-chrome bricks. After the replacement, the service life of the furnace lining increased from 200 heats to over 300 heats, which significantly reduced the maintenance cost and increased the production efficiency. Another case is a glass factory in Asia. By using directly bonded magnesia-chrome bricks in their melting furnace, they were able to reduce the frequency of furnace repairs and improve the quality of their glass products, leading to an increase in customer satisfaction and market share.

In conclusion, directly bonded magnesia-chrome bricks offer significant advantages over unfired magnesia-chrome bricks in terms of high - temperature strength, chemical stability, and service life. They are the ideal choice for industries that require reliable refractory materials in high - temperature and harsh chemical environments. If you are looking to enhance your production efficiency, reduce maintenance costs, and improve product quality, directly bonded magnesia-chrome bricks are the solution you need.

Contact us now to learn more about our directly bonded magnesia-chrome bricks and how they can help your business gain a competitive edge!